Corrosion Media Compatibility

Material and structural options designed for acids, alkalis, solvents, and reactive chemical fluids.

Wide Temperature Operation

Stable performance across low-temperature and high-temperature chemical processes.

Engineering-Grade Materials

Ceramic, PEEK, PPS, and high-performance alloys applied to critical load and corrosion areas.

OEM & System Integration Support

Integrated permanent magnet shielding, high-cleanliness fluid handling, IE5 high-efficiency motor options, and wide voltage / wide frequency operation.

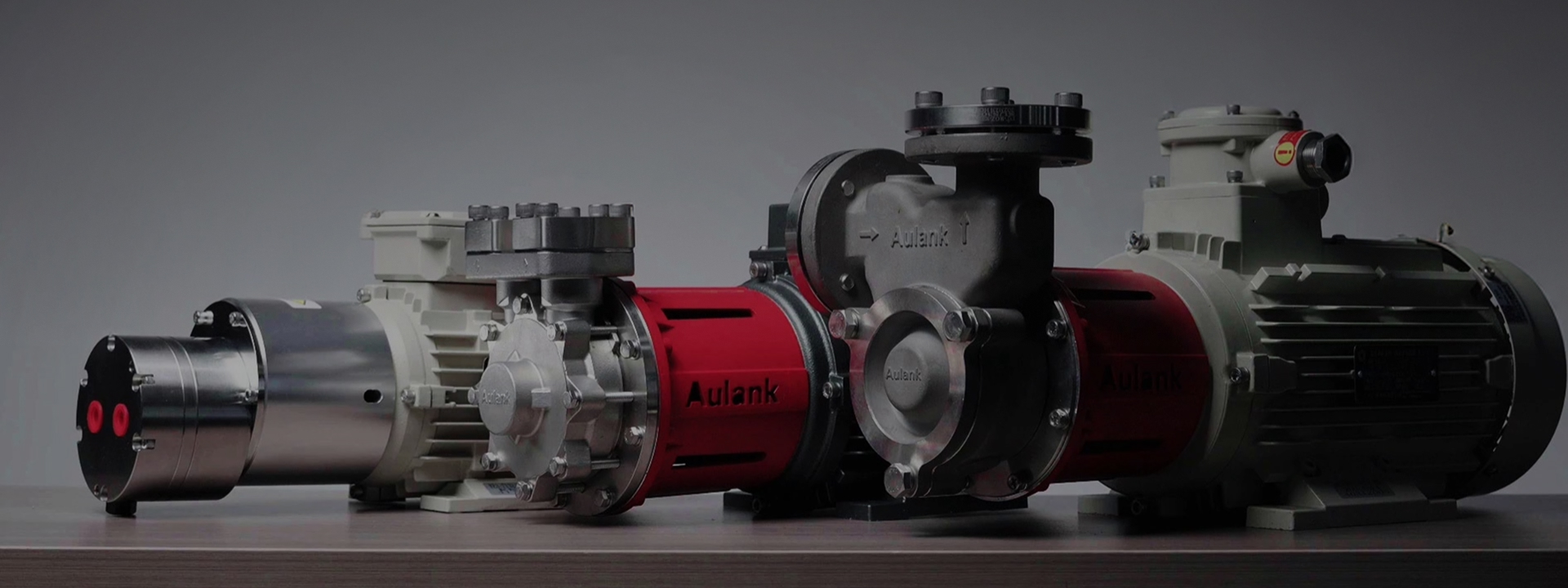

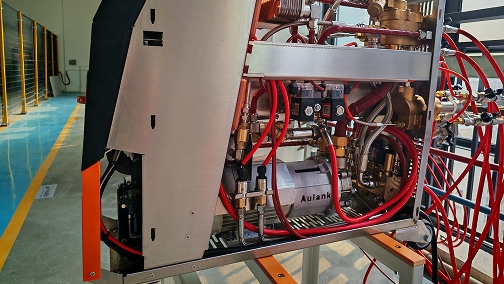

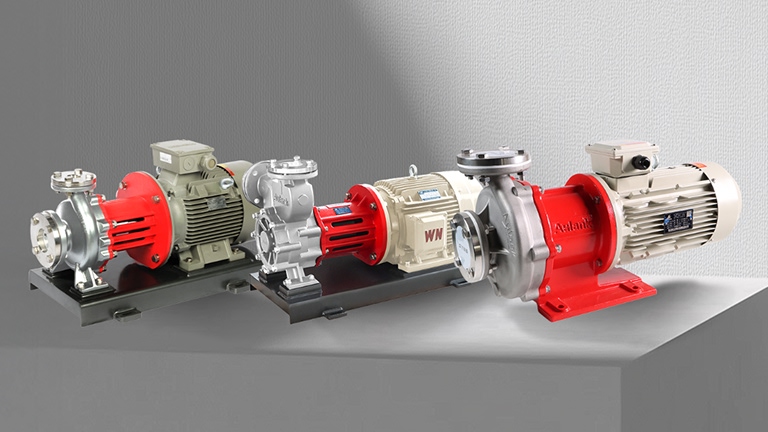

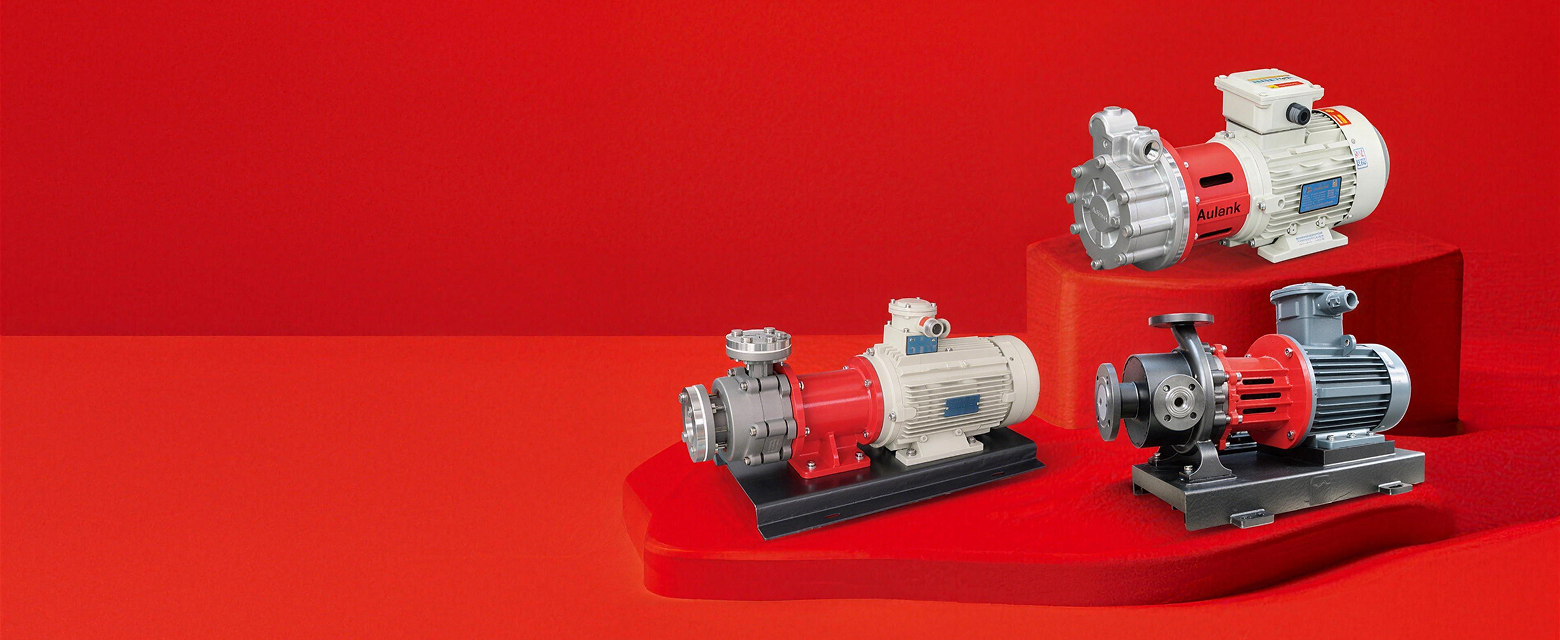

Manufacturer specialized in industrial chemical fluid transfer

Aulank is a manufacturer focused on industrial pump design and production, serving chemical processing, energy, process industries, and equipment manufacturers. We develop chemical pump systems around complex media handling and stable operation requirements, offering configurable product platforms that support both standard applications and engineering-level customization for reliable fluid transfer under real operating conditions.

Our Product

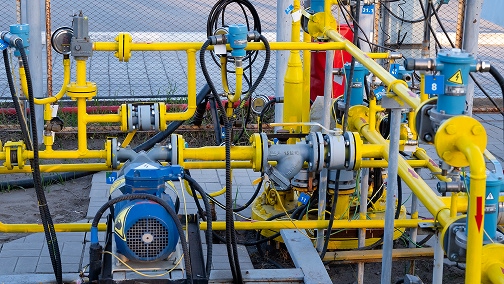

Compatible Media Types

Applications and Industries

What Matters in Chemical Pumps

Reliable chemical pump operation depends on a clear understanding of media characteristics, operating conditions, and structural design. Aulank focuses on practical application requirements by matching materials, structures, and operating stability to ensure chemical pumps perform consistently in demanding chemical environments.

Media corrosiveness and material compatibility

High and low temperature resistance

High pressure

Chemical standards

Media corrosiveness and material compatibility

High and low temperature resistance

High pressure

Chemical standards

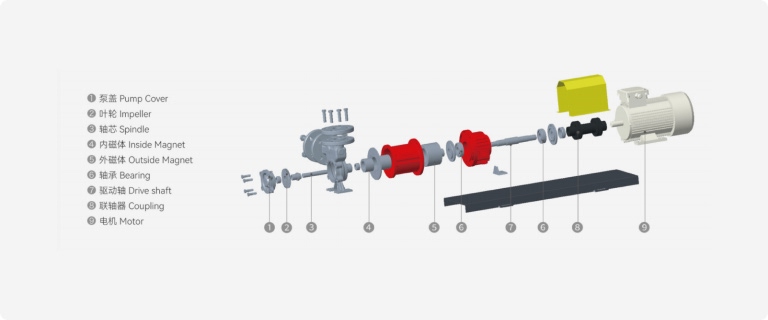

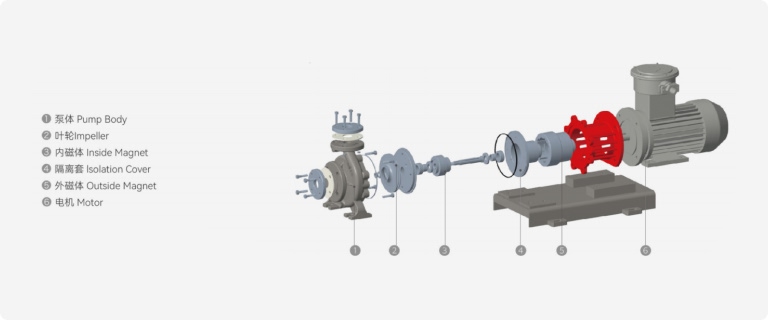

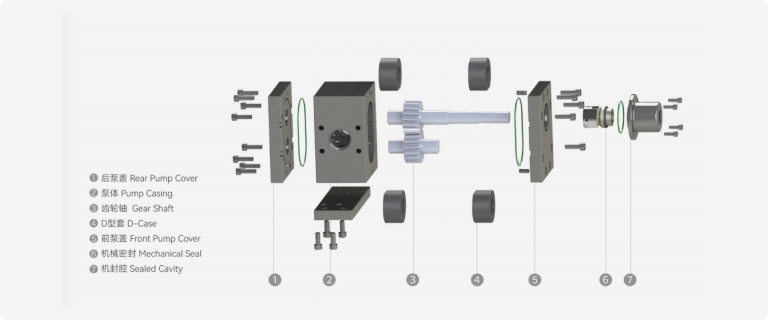

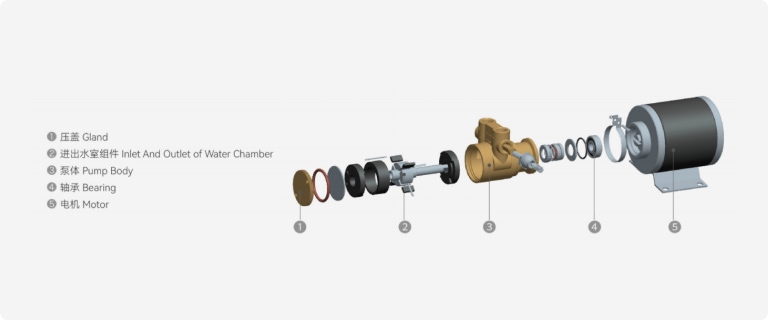

Aulank Chemical Pump Structure & Key Components

The magnetic drive regenerative pump transmits torque through inner and outer magnets without mechanical contact. The motor drives the outer magnet, which couples with the inner magnet to rotate the impeller while fully isolating the pump chamber from the motor. This design eliminates dynamic shaft seals and is suitable for corrosive, volatile, or leakage-critical chemical fluid transfer and circulation.

The magnetic drive centrifugal pump transmits torque via inner and outer magnet coupling, fully isolating the pump chamber from the motor. By eliminating mechanical shaft seals, this design is well suited for corrosive, hazardous, or leakage-critical chemical fluid transfer and continuous circulation applications.

The magnetic drive sealed gear pump combines magnet coupling with a gear pumping mechanism. Torque is transmitted through inner and outer magnets, driving synchronized gears within a sealed chamber. This design provides stable positive displacement and enhanced sealing performance, making it suitable for viscous, metering-critical, and leakage-sensitive chemical fluid transfer applications.

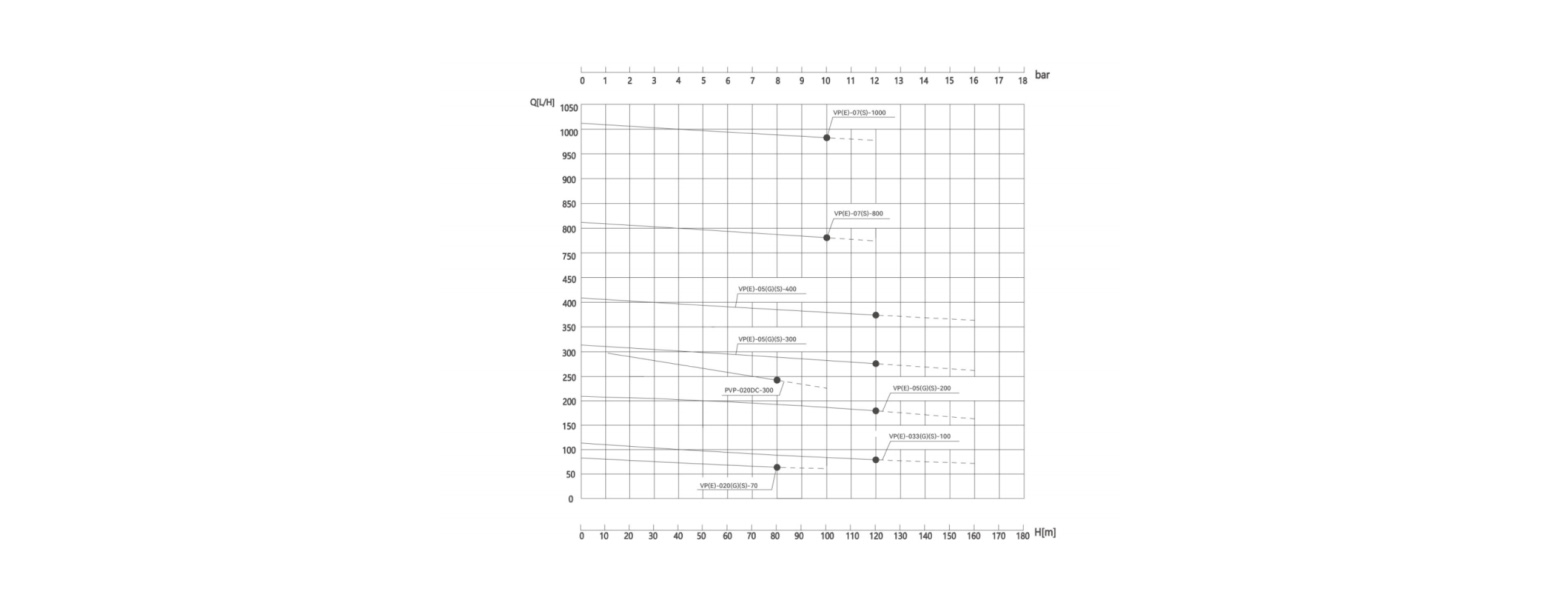

The sealed vane pump uses a positive displacement vane mechanism, where the rotor and vanes generate stable volumetric changes for smooth and continuous fluid transfer. The shaft sealing area is isolated through a sealing structure to reduce leakage risk, making it suitable for stable delivery and circulation of low- to medium-viscosity chemical fluids.

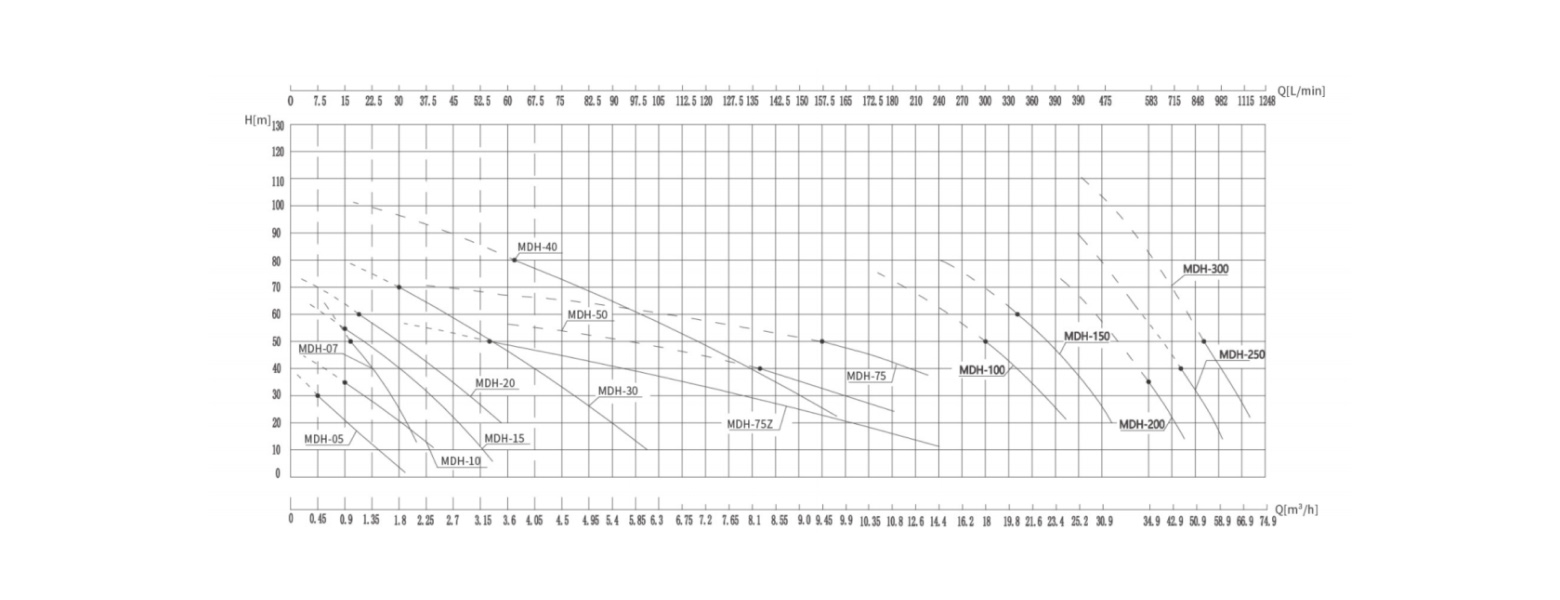

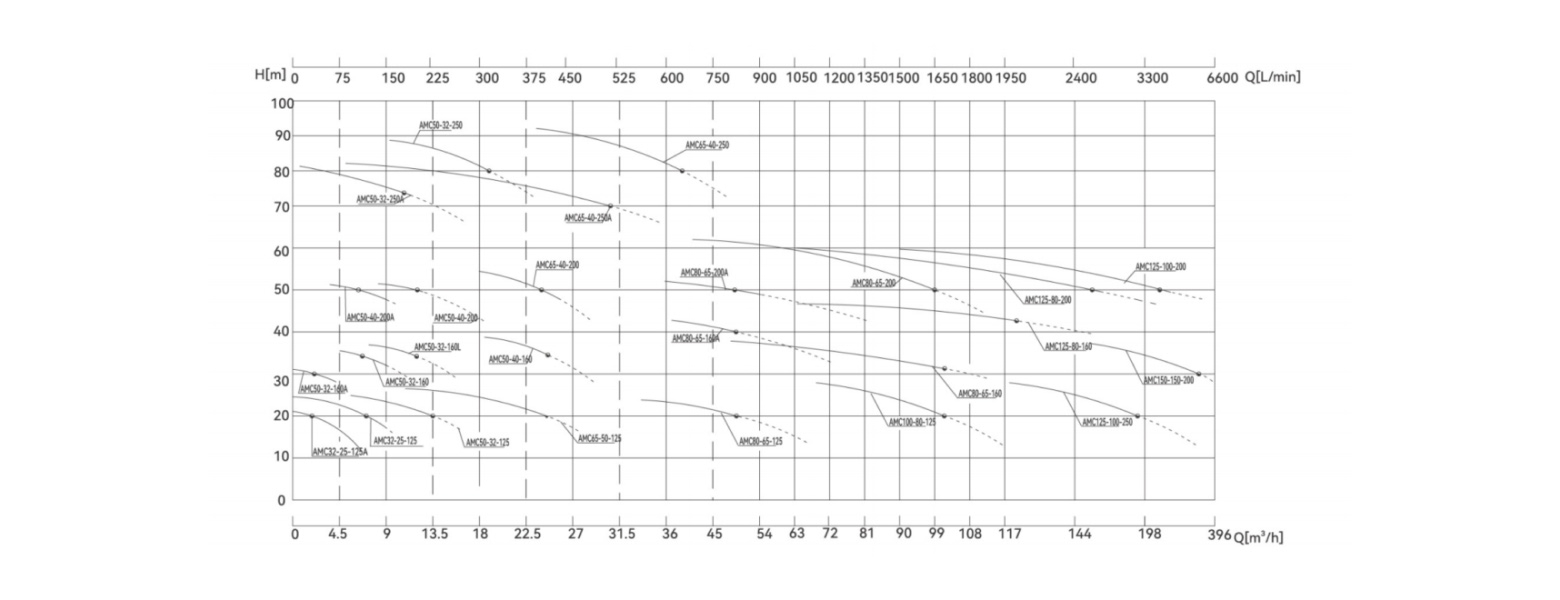

Performance Parameters & Operating Characteristics

Performance curves and technical parameters provide direct insight into pump behavior under different flow rates, head conditions, and speeds, supporting engineering evaluation and system matching.

Advanced Materials and Key Component Technologies

Material selection directly affects corrosion resistance, service life, and maintenance cost in chemical pump operation. Aulank applies engineering-grade materials and proven manufacturing processes to core components such as isolation sleeves, impellers, pump bodies, bearings, and transmission parts. By using ceramic, PEEK, PPS, Hastelloy alloys, and high-strength alloy steels, and matching them to specific fluid characteristics, we improve reliability and service life under corrosive media, high-purity fluids, and continuous-duty conditions.

Ceramic isolation sleeve

Peek isolation sleeve

Hastelloy isolation sleeve

PPS impeller

PEEK impeller

PPS pump body

Vortex impeller semi-open

Vortex impeller closed

Centrifugal impeller closed

Centrifugal impeller open

Ceramic bearings

42CrMo special steel gears

Stable Operation from - 196 °C to +400 °C

Chemical pumps often operate under low-temperature transfer, high-temperature reaction loops, and frequent thermal fluctuations. Through coordinated material systems and structural design, Aulank chemical pumps support a wide temperature range from −196 °C to +400 °C. This Optimize design reduces unplanned downtime in multi-temperature chemical systems.

Chemical Pump Selection Guide

Chemical pump selection should be based on media properties, operating conditions, and system requirements. Clear definition of key parameters at the early stage helps shorten selection time and reduce later adjustments. Key factors to consider: • Media properties (corrosiveness, viscosity, temperature, solids) • Operating temperature and pressure range • Flow rate and head requirements • Pump structure and drive type • Material compatibility and sealing design • Continuous operation and maintenance needs

Quality Control System

From raw materials and machining to final testing, Aulank applies standardized procedures and multi-stage inspections to ensure consistent performance for industrial applications.

Check Our Quality Control System

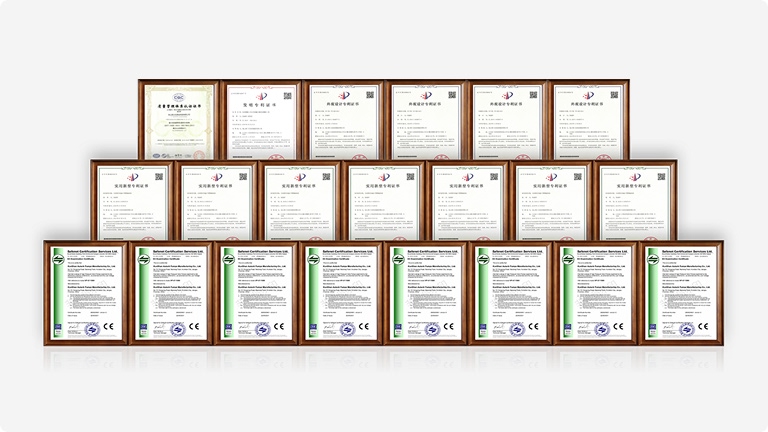

Compliance and Certifications

Products comply with relevant international standards and are supported by ISO management systems and full CE certification coverage.

Check Our Certifications

Special Customization and Engineering Configuration Support

- Permanent magnet drive with optimized isolation

- High-cleanliness fluid handling design

- IE5 high-efficiency motor configuration

- Wide-voltage and wide-frequency operating range

Aulank provides chemical pump customization based on specific media, operating conditions, and system integration needs. Customization covers pump structure, drive configuration, material systems, and motor selection to match performance, safety, and long-term stability requirements.

FAQs