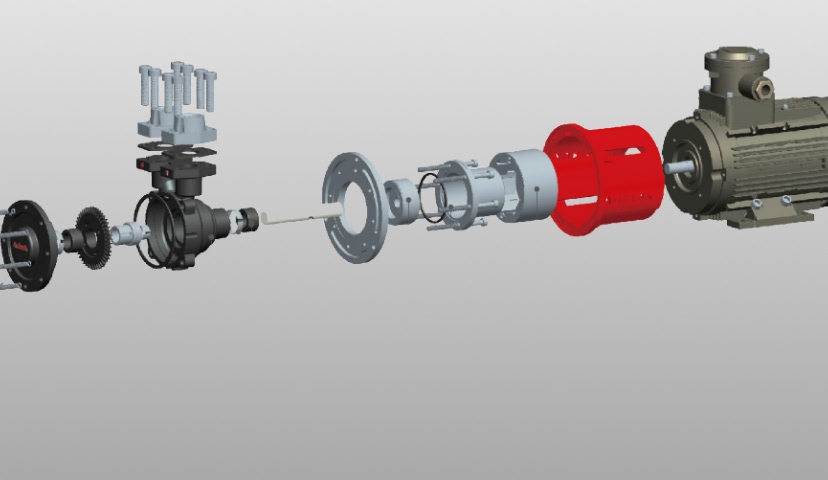

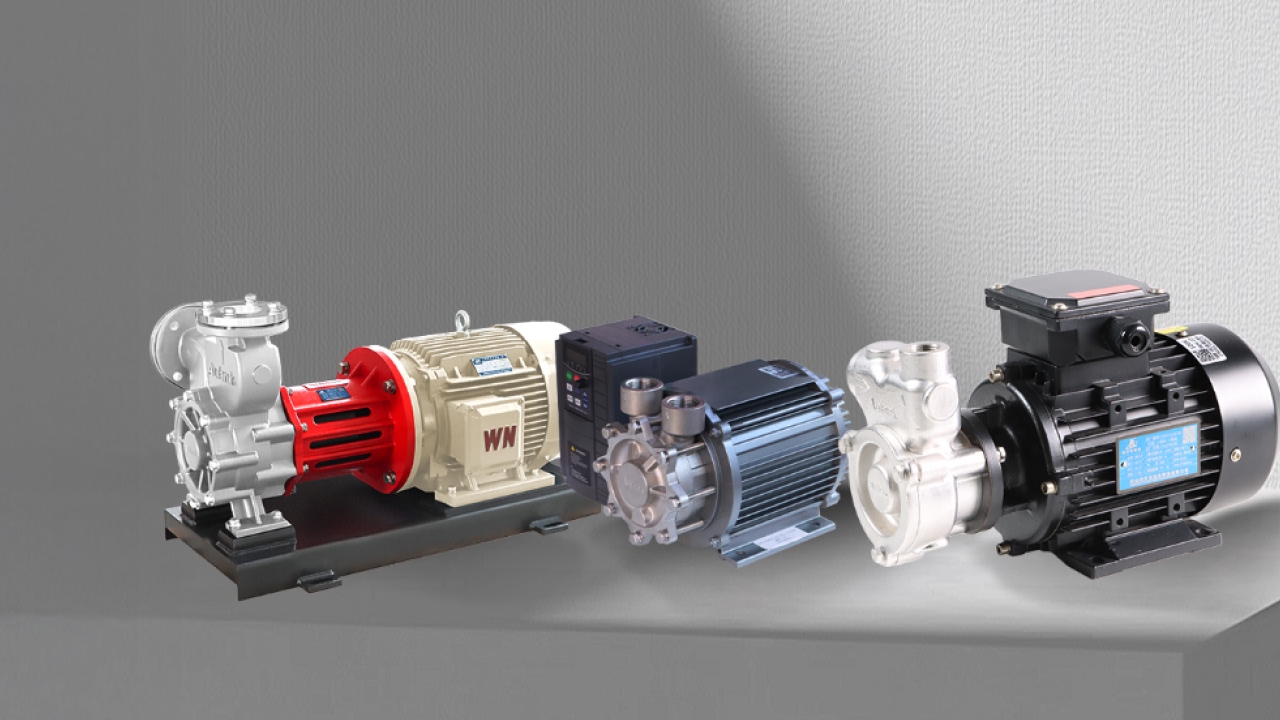

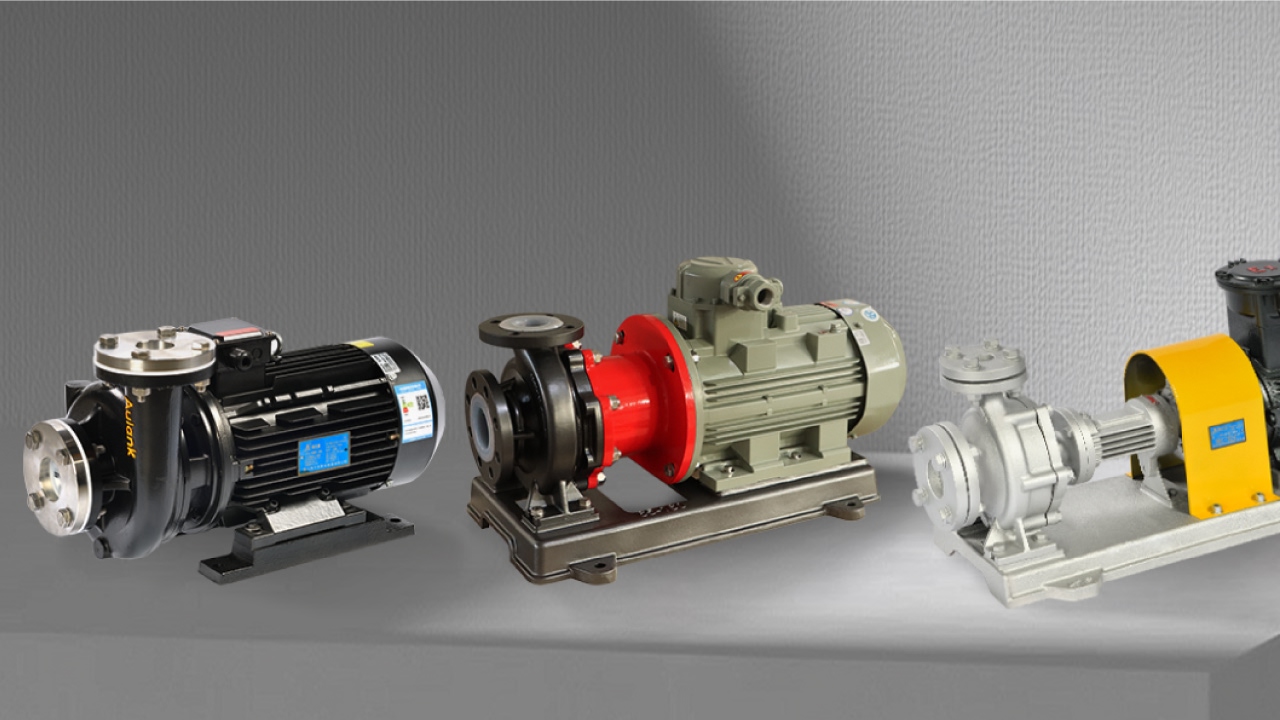

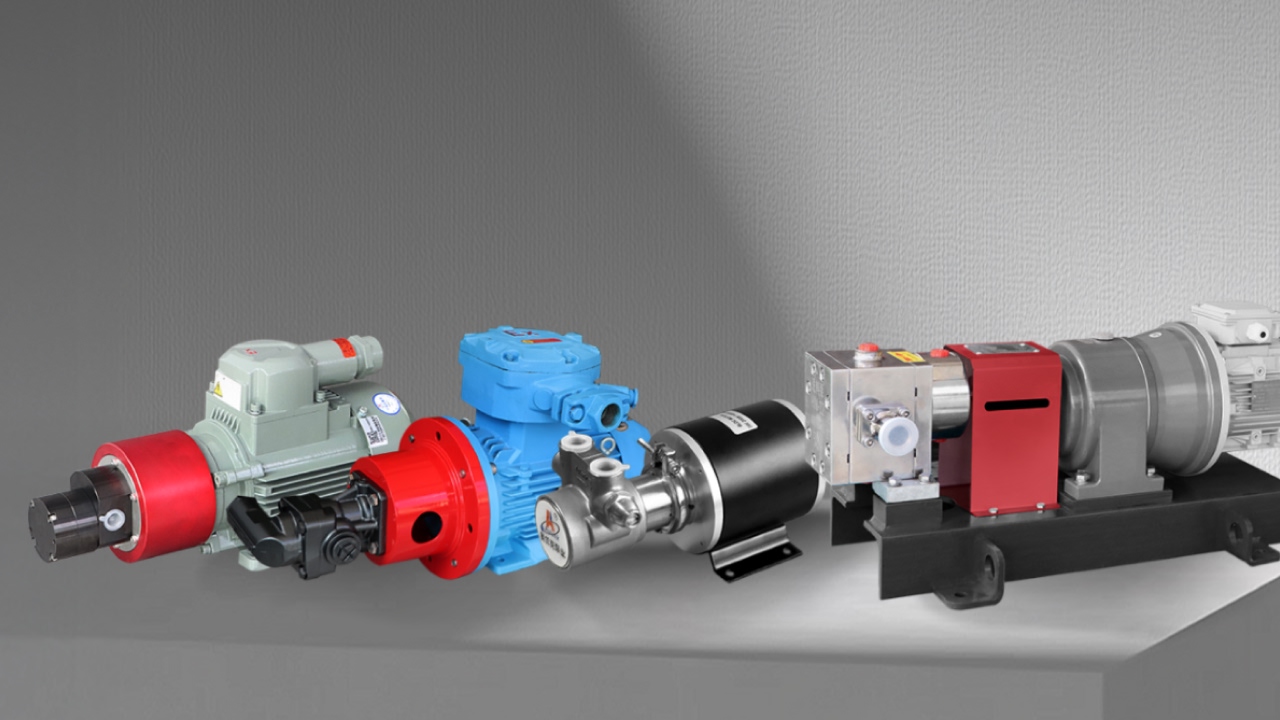

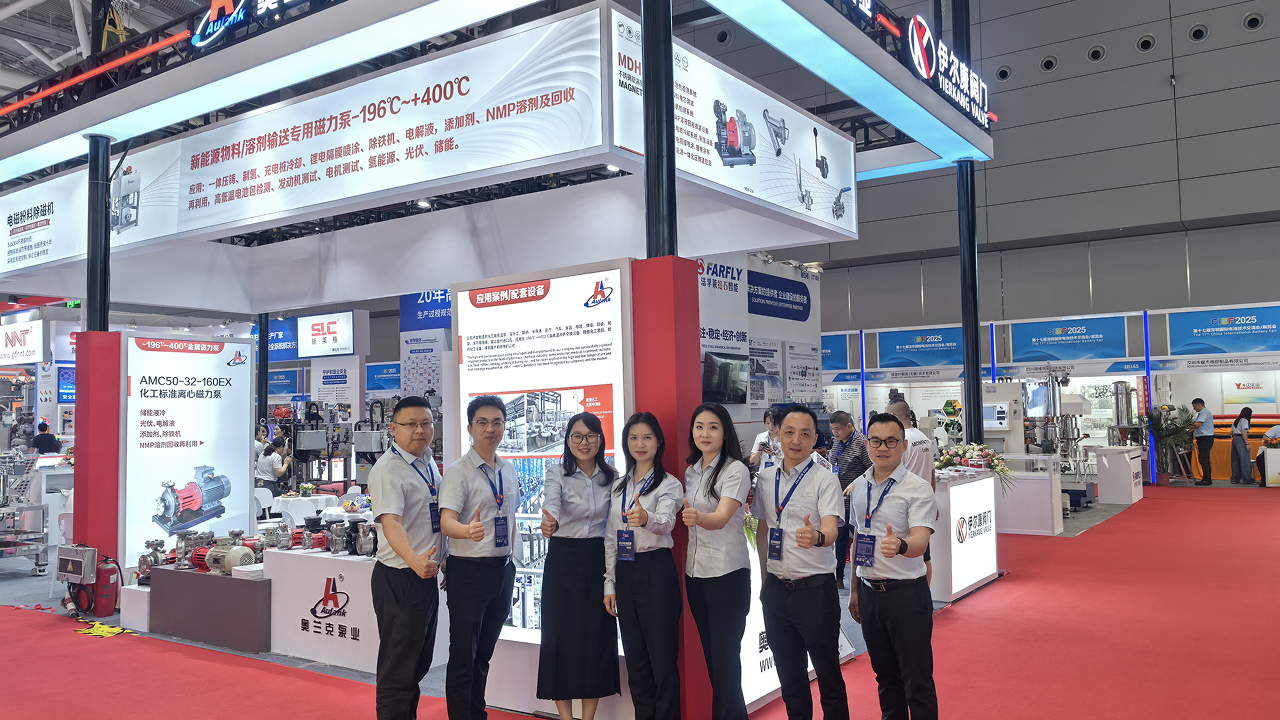

PRODUCTS

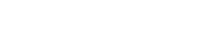

Industrial Pump Product Range

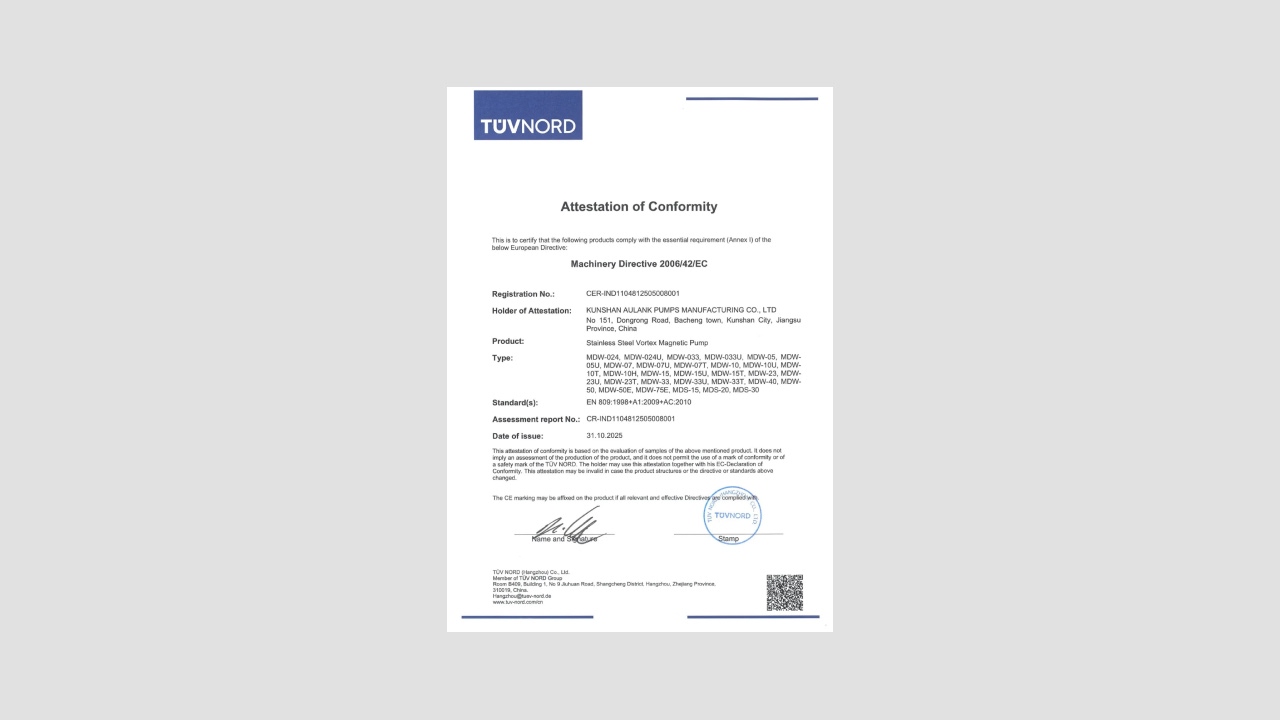

Aulank industrial pumps are engineered for real process-industry applications, with clearly defined performance targets including zero leakage, stable operation under extreme temperatures (–196°C to +400°C), chemical corrosion resistance, and long service life under continuous-duty conditions. Our pumps are designed for critical fluid transfer tasks in equipment supply and system integration.