WRY-H Coupled High-Temperature Thermal Oil Pump

Product Overview

The WRY-H Series is engineered specifically for the rigorous demands of high-temperature heat transfer. Unlike standard water pumps, this coupled centrifugal pump is designed to handle thermal oil (up to 350°C) with ease. It features a unique heat-dissipating structure with cooling fins, allowing for "air-cooled" operation that eliminates the complexity of external water cooling systems.

Product Features

- Split Structure

- Easy Maintenance

- Stable Performance

Technical Specifications

| Model | Rated Head (m) | Rated Capacity (m³/h) | Speed (r/min) | Power (kW) | Efficiency (%) | NPSH (m) | |

|---|---|---|---|---|---|---|---|

| Shaft Power | Motor Power | ||||||

| 20-20-125 | 22 | 1.5 | 2840 | 0.30 | 0.75 | 30 | 2 |

| 32-32-160 | 28 | 6.5 | 2800 | 1.91 | 1.5 | 35 | 2.3 |

| 40-25-160 | 31 | 10 | 2900 | 1.91 | 2.2 | 44 | 2.3 |

| 50-32-160 | 32 | 12.5 | 2900 | 2.31 | 3.0 | 47 | 2.3 |

| 50-32-200 | 50 | 12.5 | 2900 | 4.3 | 5.5 | 40 | 2.5 |

| 50-32-200A | 32 | 16 | 2900 | 3.7 | 4.0 | 38 | 2.6 |

| 50-32-250 | 80 | 12.5 | 2900 | 8.5 | 11 | 32 | 2.5 |

| 50-32-250A | 60 | 16 | 2900 | 8.7 | 11 | 30 | 2.5 |

| 65-50-160 | 32 | 20 | 2900 | 3.01 | 4.0 | 57.8 | 2.5 |

| 65-40-200 | 54 | 25 | 2900 | 7.07 | 7.5 | 52 | 2.5 |

| 65-40-200A | 35 | 25 | 2900 | 4.84 | 5.5 | 52 | 2.7 |

| 65-40-250 | 80 | 25 | 2900 | 11.8 | 15 | 46 | 3.0 |

| 65-40-250A | 51 | 20 | 2900 | 6.3 | 7.5 | 44 | 3.0 |

| 65-40-315 | 125 | 25 | 2900 | 22.41 | 30 | 38 | 3.0 |

| 65-40-315A | 100 | 23 | 2900 | 17.02 | 22 | 36 | 3.0 |

| 80-50-200 | 50 | 50 | 2900 | 10.8 | 15 | 61 | 3.0 |

| 80-50-200A | 42 | 45 | 2900 | 8.57 | 11 | 60 | 3.2 |

| 80-50-250 | 82 | 50 | 2900 | 19.59 | 22 | 57 | 3.0 |

| 80-50-250A | 60 | 43 | 2900 | 12.8 | 15 | 55 | 3.1 |

| 80-50-315 | 125 | 50 | 2900 | 33.41 | 45 | 51 | 3.0 |

| 80-50-315A | 100 | 45 | 2900 | 24.51 | 30 | 50 | 3.2 |

| 100-65-200 | 55 | 100 | 2900 | 20.95 | 22 | 71.5 | 4.1 |

| 100-65-200A | 44 | 94 | 2900 | 16.11 | 22 | 70 | 4.1 |

| 100-65-200B | 38 | 87 | 2900 | 13.22 | 15 | 68 | 4.2 |

| 100-65-250 | 83 | 100 | 2900 | 33.74 | 37 | 67 | 4.3 |

*The above characteristic testing is based on water transfer at normal speed under 20°C. The performance parameter error is approximately ±10%. Pump performance varies depending on the proportion and density of the liquid medium.

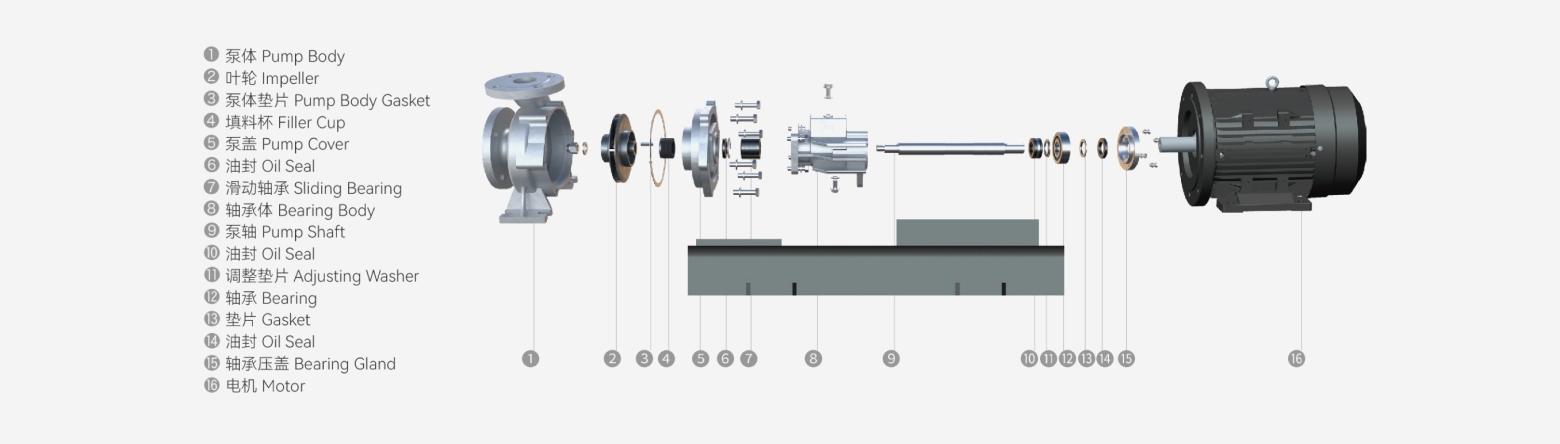

Pump Structure

The WRY-H Pump production structure consists of the Pump Body, Impeller, Pump Body Gasket, Filler Cup, Pump Cover, Oil Seal, Sliding Bearing, Bearing Body, Pump Shaft, Adjusting Washer, Bearing, Gasket, Bearing Gland, and Motor, forming a split-structure easy-maintenance stable-performance thermal fluid transfer assembly.

Working Condition

| Thermal Conductivity Oil | Ethylene glycol | Maximum Elevation | Max withstand pressure |

|---|---|---|---|

| +5°C~+350°C | -5°C~+40°C | 1000m | 10bar |

Application Area

Thermal Oil Boilers, Heat Treatment Equipment, Mold Plate Temperature Control, Roller Temperature Control, Reactor Jacket Temperature Control, etc.