RGP High-Flow Centrifugal Pump

Product Overview

While the Vortex series excels at handling solids, the RGP Series is purely focused on hydraulic efficiency and maximum flow capacity. Designed for scenarios requiring rapid fluid movement, this centrifugal pump features a precision-engineered closed impeller that minimizes energy loss, making it the "workhorse" for large-scale circulation.

Product Features

- Diversified Options for Pump Body Materials

- Imported Sealing Materials

- Stable Performance

- Compact Structure

Technical Specifications

| Model | Diameter | Motor | Performance Parameter | Pump Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Power (kW) | (Hp) | Voltage (V) | Frequency (Hz) | Speed (r/min) | Max Head (m) | Max/Use Capacity (L/min) | ||

| RGP-10 | DN40 | DN40 | 0.75 | 1 | 3ø-380 | 50 | 2760 | 18 | 165/133 | 18 |

| RGP-20 | DN50 | DN40 | 1.5 | 2 | 3ø-380 | 50 | 2760 | 22 | 235/167 | 25 |

| RGP-30 (E) | DN50 | DN40 | 2.2 | 3 | 3ø-380 | 50 | 2760 | 28 | 315/233 | 32 |

| RGP-30 (K) (Y) | DN50 | DN32 | 2.2 | 3 | 3ø-380 | 50 | 2760 | 28 | 300/200 | 28 |

| RGP-40 | DN50 | DN32 | 3 | 4 | 3ø-380 | 50 | 2900 | 35 | 300/255 | 37 |

| RGP-50 | DN50 | DN40 | 4 | 5 | 3ø-380 | 50 | 2900 | 38 | 367/267 | 60 |

| RGP-75 | DN50 | DN40 | 5.5 | 7.5 | 3ø-380 | 50 | 2900 | 42 | 400/300 | 65 |

| RGP-100 | DN65 | DN50 | 7.5 | 10 | 3ø-380 | 50 | 2900 | 50 | 680/400 | 86 |

| RGP-120 | DN65 | DN50 | 9 | 12 | 3ø-380 | 50 | 2900 | 55 | 1200/800 | 88 |

| RGP-150E | DN100 | DN100 | 11 | 15 | 3ø-380 | 50 | 2900 | 32 | 1800/1300 | 89 |

*The above characteristic testing is based on water transfer at normal speed under 20°C. The performance parameter error is approximately ±10%. Pump performance varies depending on the proportion and density of the liquid medium.

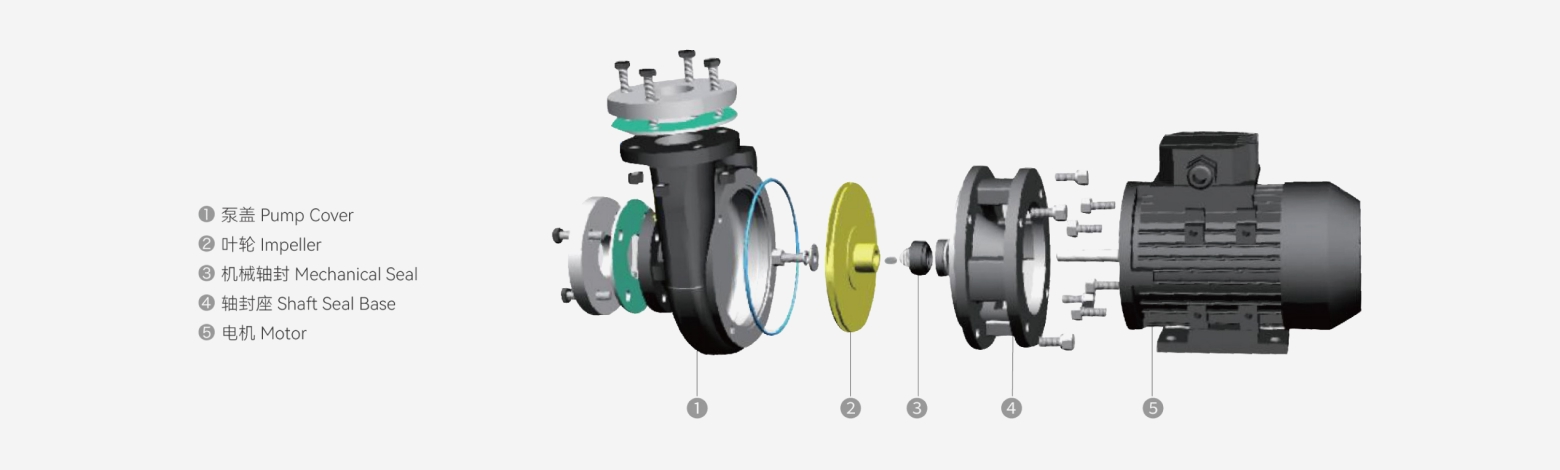

Pump Structure

The RGP Pump production structure consists of the Pump Cover, Impeller, Mechanical Seal, Shaft Seal Base, and Motor, forming a compact stable-performance high-flow fluid transfer assembly.

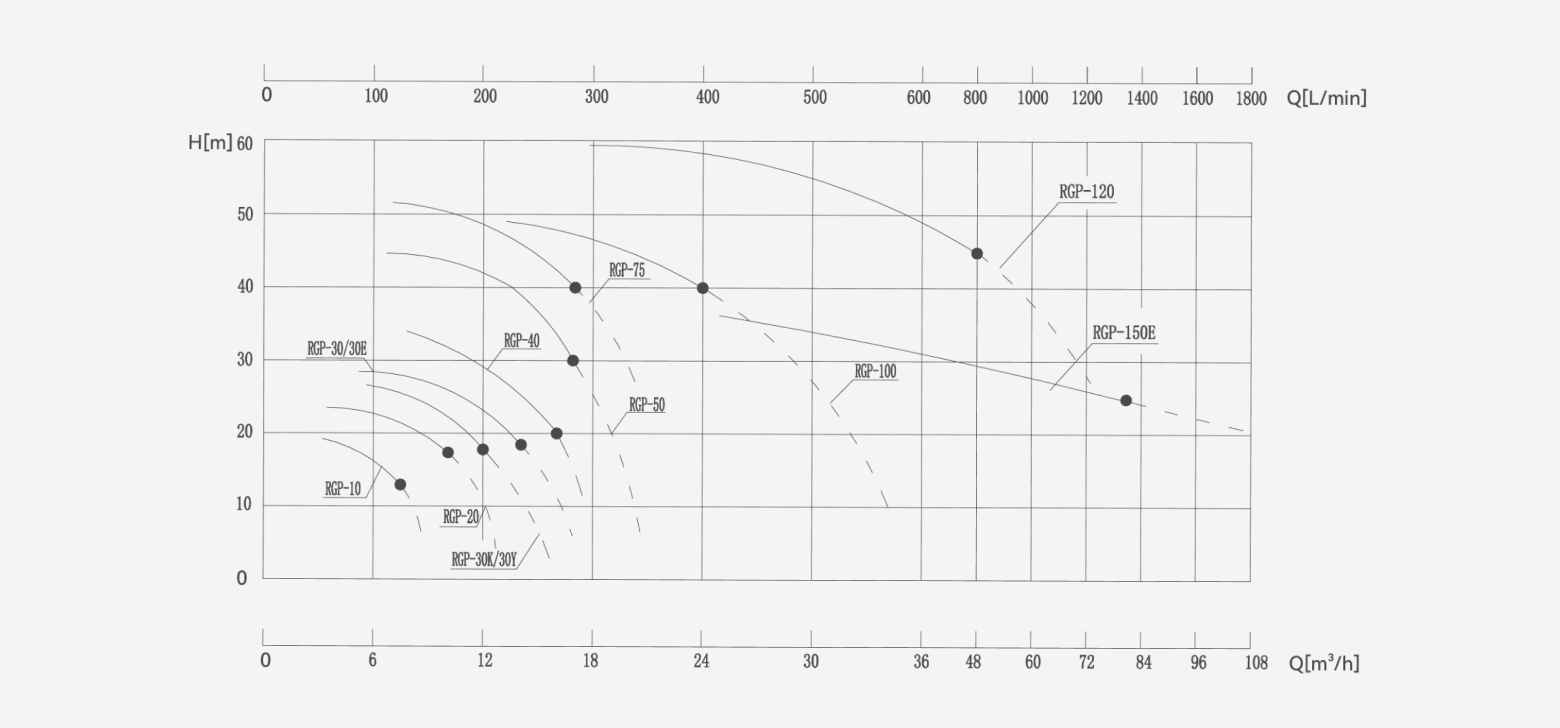

Performance Curve

The RGP Pump production structure consists of the Pump Cover, Impeller, Mechanical Seal, Shaft Seal Base, and Motor, forming a compact stable-performance high-flow fluid transfer assembly.

Working Condition

| Thermal Conductivity Water | Thermal Conductivity Oil | Ethylene glycol | Working Temperature | Maximum Elevation | Max withstand pressure |

|---|---|---|---|---|---|

| +5°C~+160°C | +5°C~+200°C | -30°C~+180°C | -5°C~+40°C | 1000m | 10bar |

Application Area

Mold Temperature Control, Roller Temperature Control, Reactor Jacket Temperature Control, Condensate Recovery, Food Equipment, Cleaning Equipment, Template Temperature Control, Barrel Temperature Control, Heat and Cold Exchange System, etc.

Product Certification