What Is a Vortex Pump?

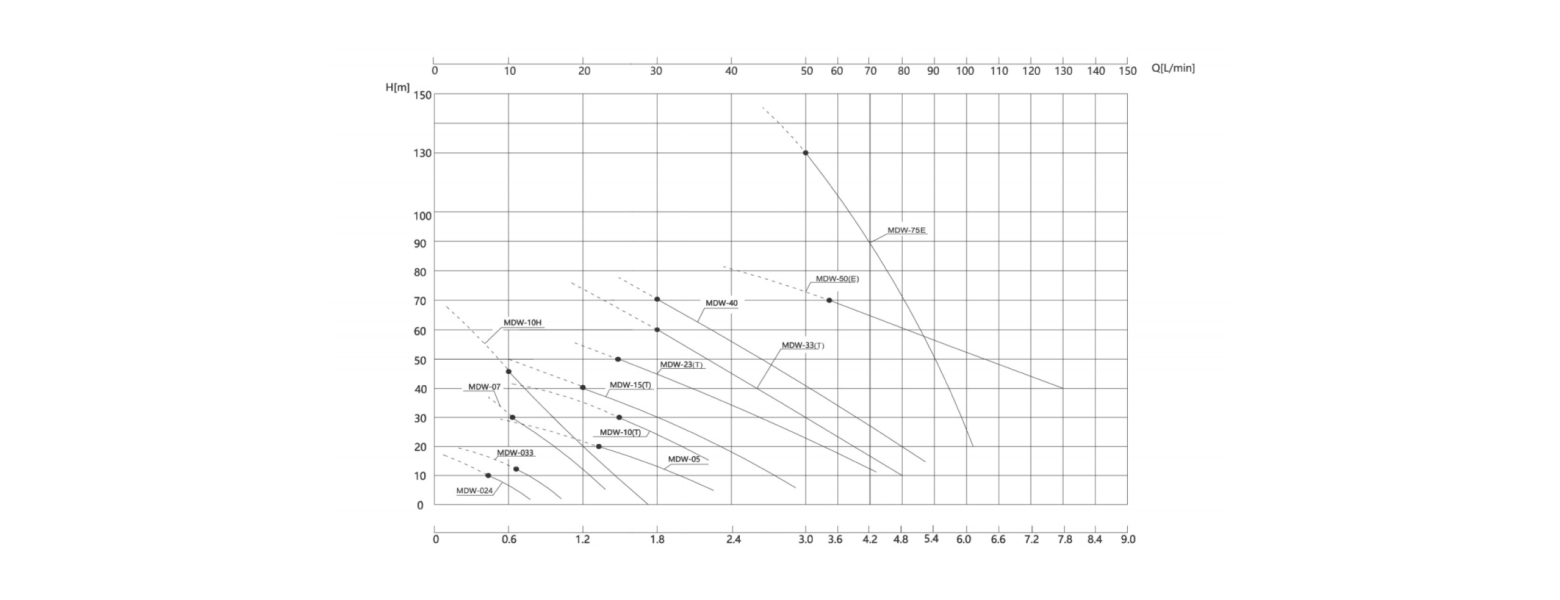

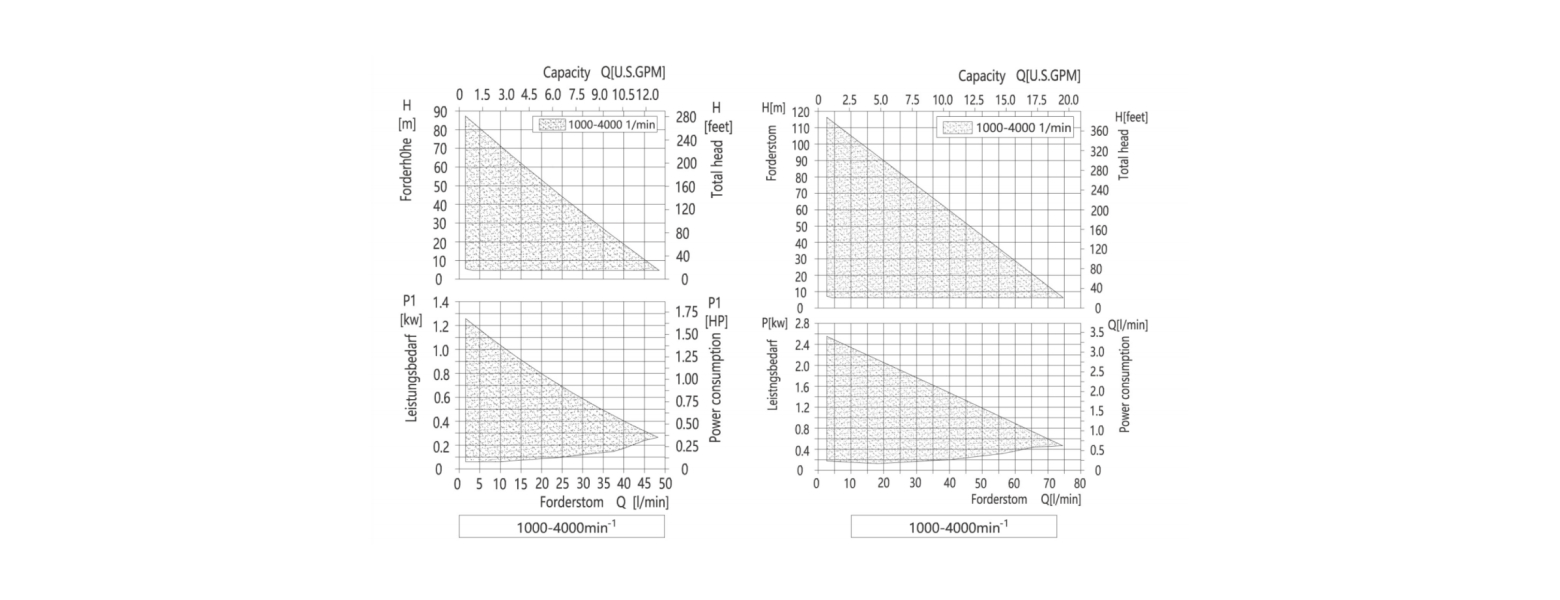

A vortex pump is a dynamic pump designed to generate high head at low flow rates through peripheral energy transfer. Compared with centrifugal pumps, vortex pumps are more suitable for compact systems requiring stable pressure under variable operating conditions.

Typical Selection Scenarios for Vortex Pumps

Vortex pumps are commonly selected for systems that require:

- High pressure with limited flow demand

- Compact installation space

- Stable pressure output under fluctuating system resistance

Vortex Pumps vs Other Pump Types

| Pump Type | Core Characteristics | Typical Applications |

|---|---|---|

| Vortex Pump | High head, low flow, compact | Precision systems, high-pressure auxiliary |

| Centrifugal Pump | Large flow, lower head | Standard transfer, circulation |

| Positive Displacement Pump | Stable flow, high differential pressure | Dosing, viscous media |

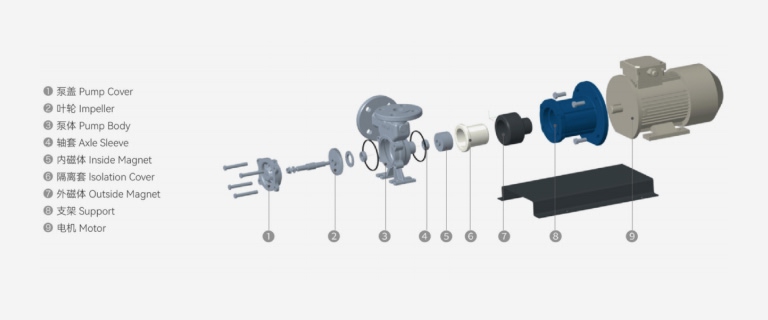

Working Principle of Vortex Pumps

Vortex pumps generate pressure by repeatedly accelerating fluid along the impeller periphery. This allows pressure to build up progressively, achieving high head output even at low flow rates.

Operation and Maintenance Considerations

Stable operation depends on:

- Proper duty point selection

- Temperature rise control

- Avoidance of prolonged dry running

- Clean media and stable inlet conditions