MDW Stainless Steel Vortex Magnetic Pump

Product Overview

MDW Series Magnetic Drive High-Low Temperature Vortex Pumps feature wetted parts made of stainless steel, brass, and cast iron. Adopting advanced hydraulic technology, highly efficient magnetic drive structures, and innovative appearance design, these pumps achieve the advantages of energy efficiency, safety, reliability, stable performance, and long service life through precision processing and manufacturing techniques. They are widely used in mid-to-high-end application fields.

Product Features

- The impeller adopts a highly wear-resistant surface treatment process

- Capable of forward and reverse fluid transfer

- High-pressure resistant technology.

- High-strength and wear-resistant technology for isolation sleeves

- Multiple spindle configurations available for high-temperature and high-pressure conditions

Technical Specifications

| Model | Diameter | Motor | Performance Parameter | Pump Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Power (kW) | (Hp) | Voltage (V) | Frequency (Hz) | Speed (r/min) | Max/Rated Head (m) | Max Capacity (L/min) | ||

| MDW-024 | DN15 | DN15 | 0.18 | 0.24 | 3ø-380 | 50 | 2760 | 15/10 | 15 | 7.5 |

| MDW-033 | DN15 | DN15 | 0.25 | 0.33 | 3ø-380 | 50 | 2760 | 20/12 | 15 | 9 |

| MDW-05 | DN15 | DN15 | 0.37 | 0.5 | 3ø-380 | 50 | 2760 | 30/20 | 30 | 9.5 |

| MDW-07 | DN15 | DN15 | 0.5 | 0.7 | 3ø-380 | 50 | 2760 | 40/30 | 25 | 10 |

| MDW-07T | G1/2" | G1/2" | 0.5 | 0.7 | 3ø-380 | 50 | 2760 | 50/40 | 40 | 10 |

| MDW-10H | DN15 | DN15 | 0.75 | 1 | 3ø-380 | 50 | 2760 | 75/50 | 30 | 10 |

| MDW-10 (T) | DN20 | DN20 | 0.75 | 1 | 3ø-380 | 50 | 2760 | 45/30 | 45 | 10 |

| MDW-15 (T) | DN20 | DN20 | 1.1 | 1.5 | 3ø-380 | 50 | 2760 | 60/40 | 60 | 17 |

| MDW-23 (T) | DN25 | DN25 | 1.7 | 2.3 | 3ø-380 | 50 | 2760 | 65/50 | 90 | 22 |

| MDW-33 (T) | DN25 | DN25 | 2.5 | 3.3 | 3ø-380 | 50 | 2760 | 90/60 | 90 | 26 |

| MDW-40 | DN25 | DN25 | 3 | 4 | 3ø-380 | 50 | 2900 | 100/70 | 100 | 35 |

| MDW-50 (E) | DN32 | DN32 | 4 | 5 | 3ø-380 | 50 | 2900 | 90/70 | 200 | 55 |

| MDW-75E | DN40 | DN40 | 5.5 | 7.5 | 3ø-380 | 50 | 2900 | 220/130 | 106 | 60 |

*The above characteristic testing is based on water transfer at normal speed under 20°C. The performance parameter error is approximately ±10%. Pump performance varies depending on the proportion and density of the liquid medium.

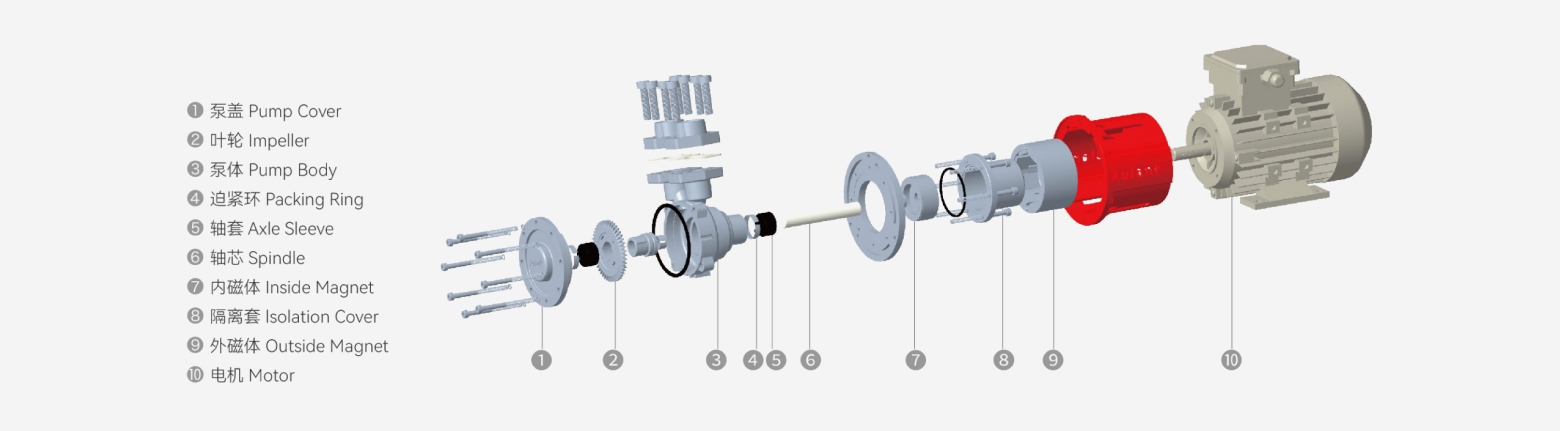

Pump Structure

The MDS Pump production structure consists of the Pump Cover, Spindle, Impeller, Pump Body, Axle Sleeve, Packing Ring, Inside Magnet, Isolation Cover, Outside Magnet, and Motor, forming a wear-resistant leak-proof cryogenic and high-temperature fluid transfer assembly.

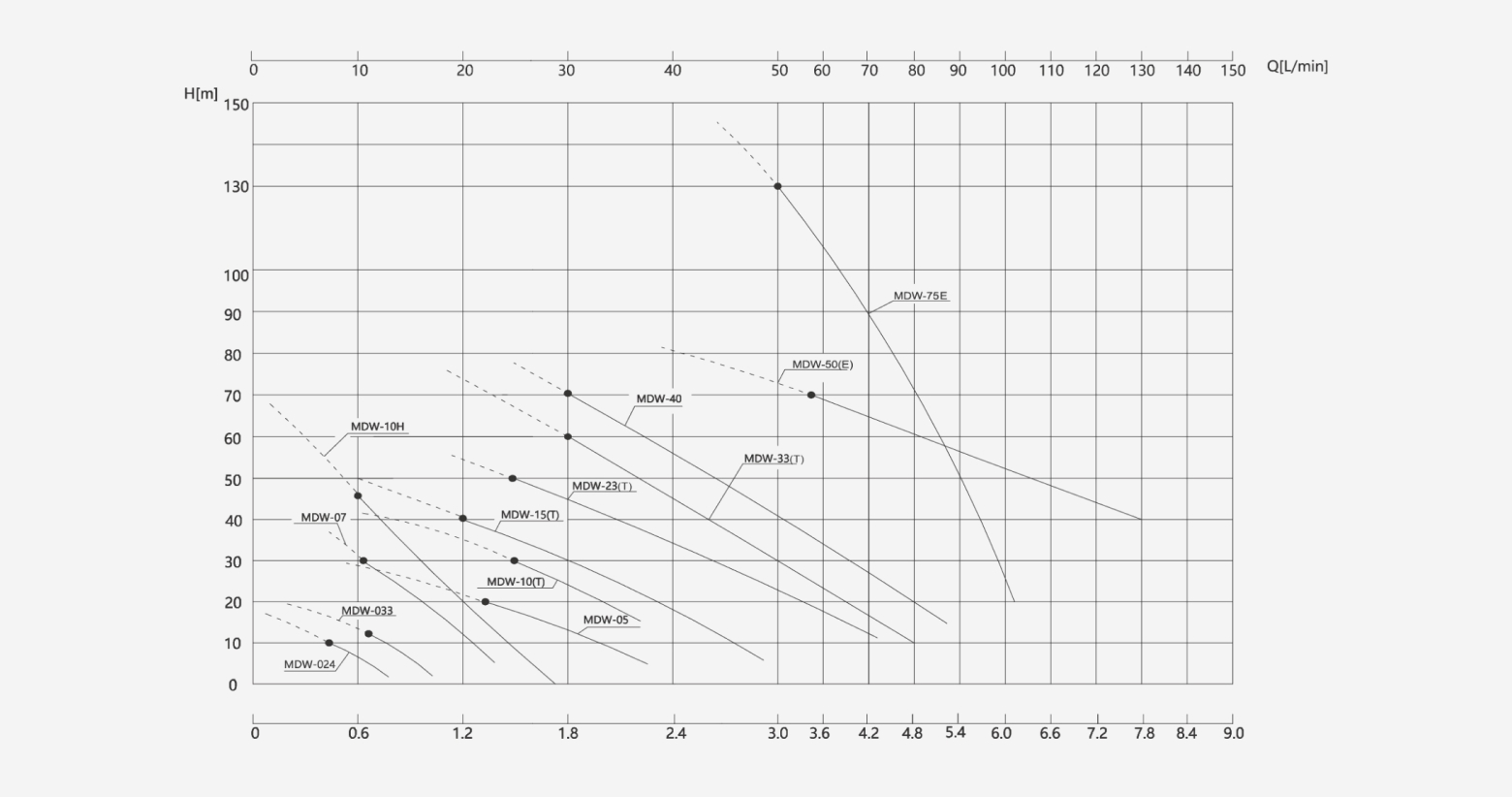

Performance Curve

The MDS Pump production structure consists of the Pump Cover, Spindle, Impeller, Pump Body, Axle Sleeve, Packing Ring, Inside Magnet, Isolation Cover, Outside Magnet, and Motor, forming a wear-resistant leak-proof cryogenic and high-temperature fluid transfer assembly.

Working Condition

| Medium Temperature | Medium Density | Ambient Temperature | Maximum Elevation | Max Withstand Pressure |

|---|---|---|---|---|

| -196°C ~ +400°C | 0.6 ~ 2.0 | -50°C ~ +70°C | 5000m | 70bar |

Application Area

High-Temperature Mold Temperature Control, High-Low Temperature Test Instruments, Semiconductor Precision Temperature Control, Chemical Equipment, Template Temperature Control, Ultrasonic Cleaning Equipment, High-End Printing and Dyeing Equipment, TCU Temperature Control Systems, etc.

Product Certification