Quality Control Process

The quality control process covers the complete manufacturing chain from incoming materials and assembly to in-process control, testing, and shipment. Standardized inspection requirements and record mechanisms are established at key production stages. Process control and data retention are implemented through production work orders, inspection records, and test forms to ensure consistency and stability throughout manufacturing.

Incoming Inspection

All incoming materials are registered with receiving records by the warehouse department and inspected and documented by the quality department. Materials are approved for storage only after passing inspection. Key components are subject to sampling inspection or full inspection according to inspection standards to ensure that raw material quality meets production requirements.

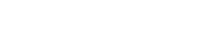

Assembly Process Control

The manufacturing department organizes assembly based on production work orders and performs process confirmation using assembly self-inspection checklists. Standardized assembly procedures and self-check mechanisms help reduce human variation and ensure assembly consistency.

In-Process Inspection

The quality department conducts in-process inspections at key production stages based on production work orders. Process deviations are identified and corrected in a timely manner to ensure that manufacturing activities remain controlled and compliant with process requirements.

Performance Testing

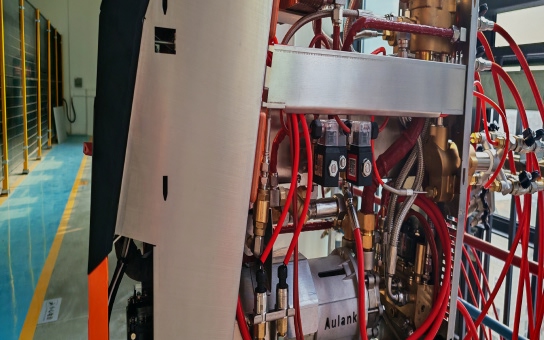

The testing department performs performance testing on each pump and completes pump performance test records. Operating parameters are measured and verified to ensure that product performance meets design and application requirements.

Finished Product Inspection

The quality department conducts finished product inspections on assembled pumps and generates finished inspection records, confirming that appearance, assembly condition, and functional performance meet shipment standards.

Shipment Inspection

All outgoing products must pass shipment inspection, with corresponding shipment inspection records generated to ensure product condition integrity and information traceability at delivery.

Quality Management

Supplier Evaluation

We implement evaluation and management procedures for key component and raw material suppliers, assessing quality stability and delivery capability to ensure a reliable supply chain that meets product quality and delivery requirements.

Incoming Quality Inspection

Incoming materials are inspected by sampling or full inspection in accordance with inspection standards, with a focus on critical dimensions, material properties, and appearance quality to prevent non-conforming materials from entering production.

Manufacturing Process Control

Through standardized manufacturing processes and defined quality control points, full-process quality management is implemented to ensure that each operation is carried out according to specifications and to reduce quality variation risks.

Finished Product Testing

All pump products undergo 100% testing before shipment. Key test parameters are recorded via QR codes, enabling traceability between products and their test data.

Shipment Inspection

Before shipment, product condition, identification, and inspection records are comprehensively checked to ensure that delivered products meet quality requirements and provide reliable performance assurance.

Inspection Equipment

Pneumatic Precision Measuring Instrument

Used for dimensional inspection of precision components where high accuracy and repeatability are required.

Coordinate Measuring Machine (CMM)

Used for dimensional and geometric inspection of precision parts, supporting multi-axis and complex structure measurement.

Flatness Measuring Instrument

Used for flatness measurement of impellers and related components.

Alloy Analyzer

Used for material composition analysis of metal components, commonly applied in incoming inspection and key part verification.

Optical Measuring System

Used for dimensional measurement of precision parts, suitable for contour and positional inspection.

High-Temperature Thermal Testing Equipment

Used to simulate high-temperature conditions for thermal performance testing of magnetic components and related parts.