What Is a Centrifugal Pump?

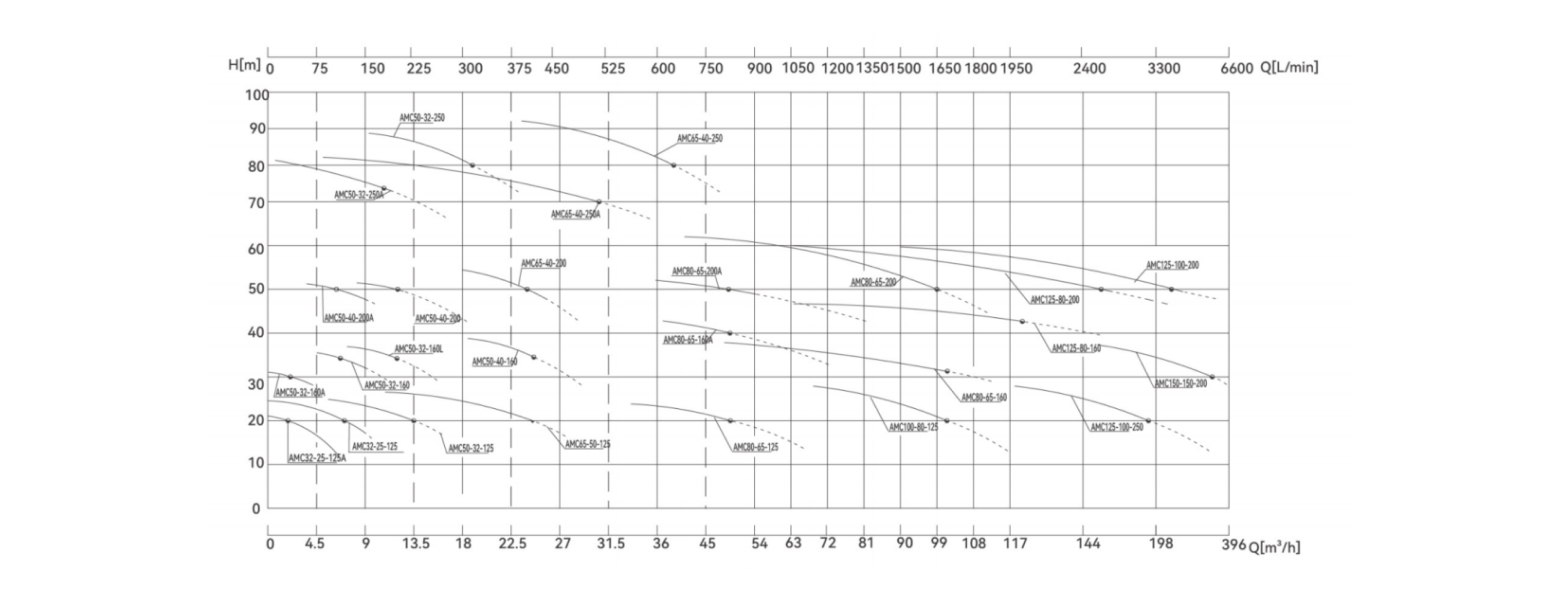

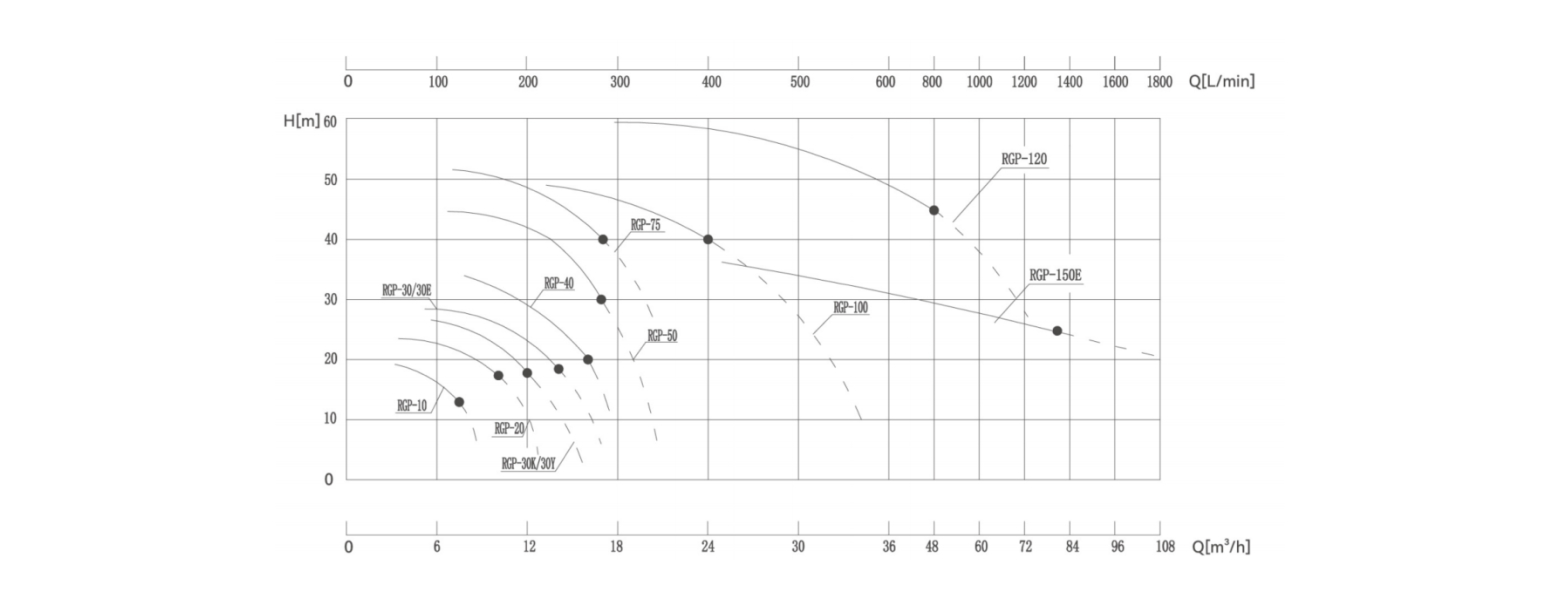

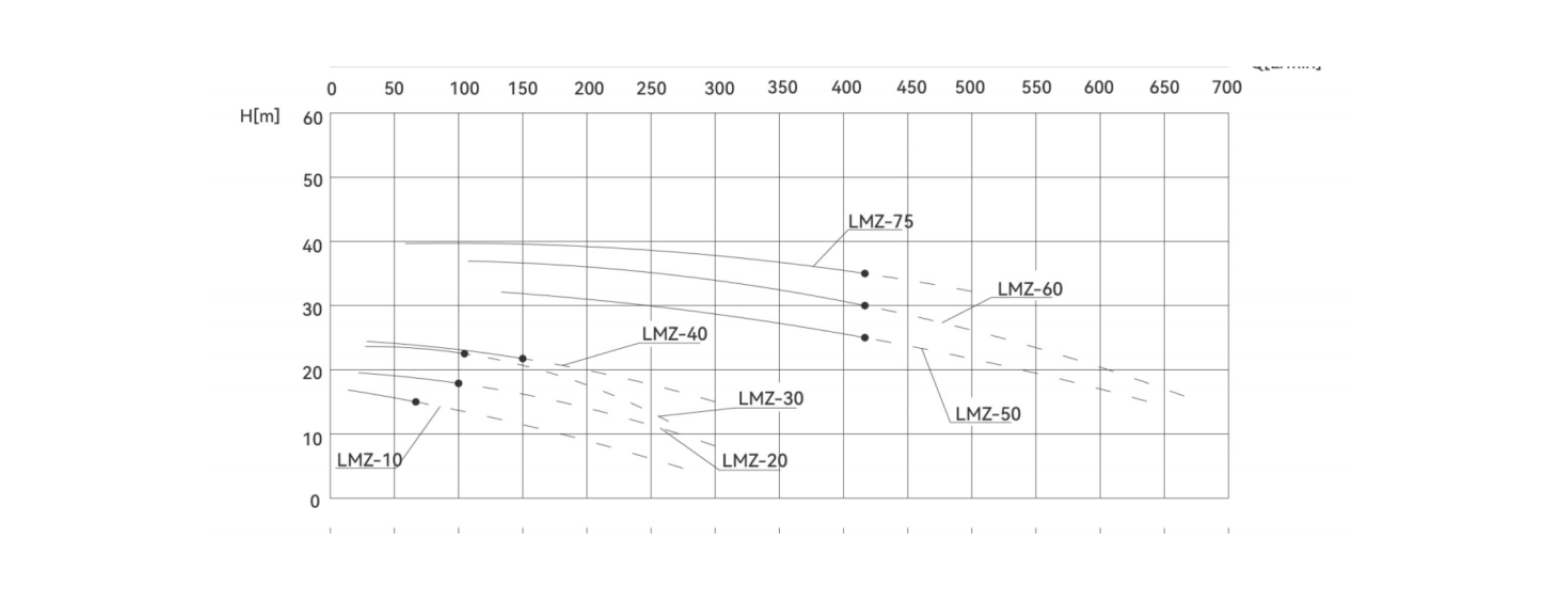

At its core, a centrifugal pump moves fluid by spinning an impeller. The rotation throws the liquid outward, and that outward motion generates pressure — which is what pushes the fluid through your piping system. It's the most common pump type in industrial settings, and for good reason: it handles continuous, high-volume flow well and works reliably across a wide range of liquids.

How Does a Centrifugal Pump Work?

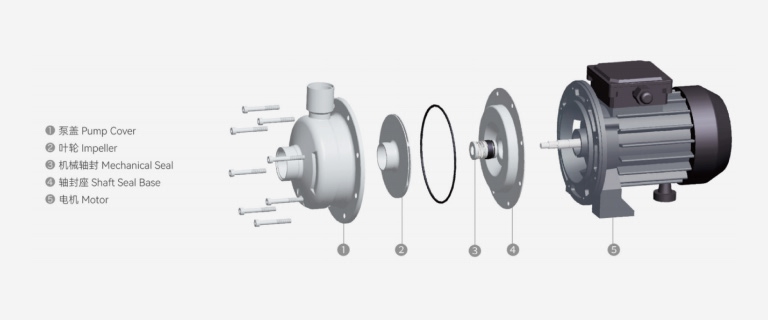

The motor spins the impeller at high speed. As it does, the fluid inside gets thrown outward — centrifugal force at work. That leaves a low-pressure pocket at the center of the impeller, which pulls fresh fluid in through the suction line. The fast-moving fluid leaving the impeller then enters the volute casing, where the wider path slows it down and converts that velocity into pressure. The trade-off between flow rate and head depends on impeller design, RPM, and how much resistance your system puts back — that's exactly what the performance curve maps out.

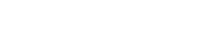

Magnetic Drive vs. Mechanical Seal — How to Choose?

With a magnetic drive pump, there's no shaft going through the casing wall at all. Torque transfers through a magnetic coupling, which keeps the fluid side completely sealed off from the motor side. No seal to wear, no leak path to worry about. That's why magnetic drive is the go-to choice when you're handling anything toxic, corrosive, or volatile.

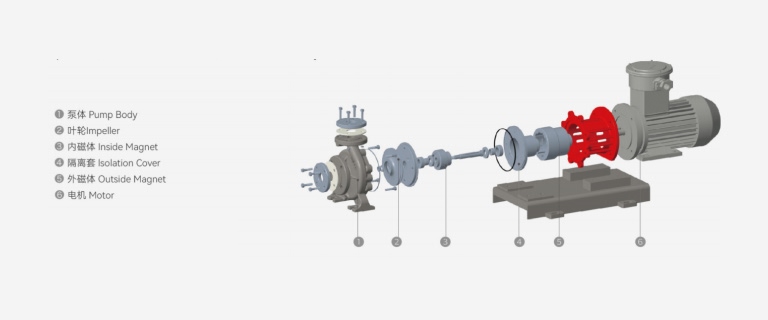

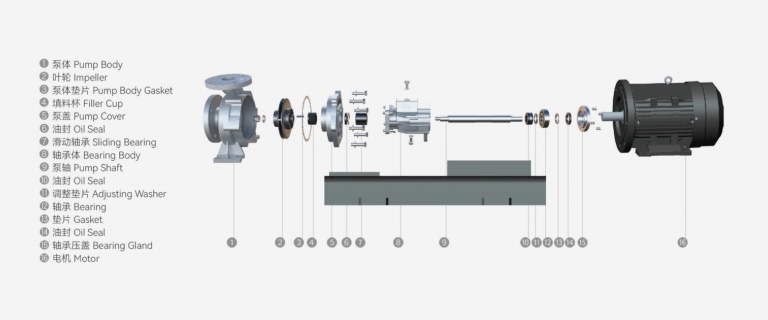

Mechanical seal pumps use a direct shaft connection with a precision seal where the shaft passes through the casing. They handle higher flow rates and cost less upfront, and they're the standard choice for general-purpose or non-hazardous fluids. Parts are easy to find and maintain.

Bottom line: if your media is hazardous, go magnetic drive. If it's not, mechanical seal is the practical choice.

How to Maintain a Centrifugal Pump?

Mechanical seals are the first thing to watch. Check them regularly and replace before you actually see leakage — by that point you've already got a problem. Bearing temperature and vibration should be monitored during normal operation; unusual changes usually signal something early. Keep the suction line clear — blockages lead to cavitation, which damages the impeller faster than almost anything else. For magnetic drive units, inspect the containment shell periodically for any corrosion or cracking. If a pump sits idle for weeks, turn it over by hand occasionally to keep the bearings from seizing up.

Industrial Pump Type Comparison

| Pump Type | Drive Principle | Flow Stability | Self-Priming | Suitable Media | Typical Flow | Main Application |

|---|---|---|---|---|---|---|

| Centrifugal Pump | Impeller centrifugal force | Varies with system pressure | Needs priming or submersion | General liquids, moderate viscosity | Medium to large | Continuous high-flow transport |

| Vortex Pump | Impeller vortex energy transfer | Stable at given speed | Good | Liquids with solids or entrained gas | Small to medium | Small flow, high head, self-priming needs |

| Gear Pump | Gear mesh volume displacement | Very stable, pressure-independent | Good | High viscosity, clean or lightly contaminated | Small to medium | Precision metering, lube oil systems |

| Screw Pump | Screw rotor volume displacement | Very stable | Good | High viscosity, abrasive, multiphase | Small to medium | Viscous or abrasive media |

| Magnetic Drive Pump | Centrifugal + magnetic coupling | Same as base centrifugal type | Same as base type | Toxic, corrosive, volatile media | Small to large | Leak-free chemical processing |

| Diaphragm Pump | Diaphragm volume change | Pulsating | Good | Corrosive, abrasive, slurry | Small | Chemical dosing, slurry transfer |