MDC-K Magnetic / Mechanical Seal Gear Pump

Product Overview

The MDC-K Series is built for applications where standard pumps fail. Distinguishing itself from the general-purpose MDC-X, the MDC-K is a heavy-duty powerhouse capable of withstanding system pressures up to 100 bar and operating in extreme temperatures from -120°C to +150°C.

Product Features

- Wide Operating Temperature Range of -60°C to 250°C

- High Volumetric Efficiency

- High Machining Precision

- Noise Level Below 70 dB

- Wide Viscosity Range Handling of 1–20,000 cP

Technical Specifications

| Model | ED | Unit | Pressure (Performance at 1450 r/min) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2Bar | 4Bar | 6Bar | 8Bar | 10Bar | 15Bar | 20Bar | 25Bar | |||

| MDC-K4 | 4 | L/min | 5.7 | 5.6 | 5.6 | 5.5 | 5.4 | 5.3 | 5.1 | 4.9 |

| KW | 0.25 | 0.25 | 0.25 | 0.25 | 0.37 | 0.37 | 0.37 | 0.37 | ||

| MDC-K6 | 6 | L/min | 9 | 8.9 | 8.8 | 8.7 | 8.6 | 8.3 | 8 | 7.8 |

| KW | 0.25 | 0.25 | 0.25 | 0.37 | 0.37 | 0.55 | 0.55 | 0.75 | ||

| MDC-K8 | 8 | L/min | 11.3 | 11.2 | 11.1 | 10.9 | 10.9 | 10.5 | 10.2 | 9.8 |

| KW | 0.25 | 0.25 | 0.37 | 0.37 | 0.55 | 0.53 | 0.75 | 0.75 | ||

| MDC-K10 | 10 | L/min | 14.2 | 14.1 | 14 | 13.8 | 13.6 | 13.2 | 12.8 | 12.4 |

| KW | 0.25 | 0.25 | 0.25 | 0.37 | 0.55 | 0.55 | 0.75 | 1.1 | ||

| MDC-K12 | 12 | L/min | 17.2 | 17.1 | 17 | 16.9 | 16.8 | 16.5 | 15.9 | 15.4 |

| KW | 0.25 | 0.25 | 0.37 | 0.55 | 0.55 | 0.75 | 1.1 | 1.1 | ||

| MDC-K16 | 16 | L/min | 22.6 | 22.4 | 22.2 | 22 | 21.7 | 21.1 | 20.5 | 19.8 |

| KW | 0.37 | 0.37 | 0.55 | 0.55 | 0.75 | 1.1 | 1.1 | 1.5 | ||

| MDC-K20 | 20 | L/min | 29.77 | 28.9 | 28.03 | 27.4 | 27.1 | 26.4 | 25.6 | 24.7 |

| KW | 0.37 | 0.55 | 0.55 | 0.75 | 1.1 | 1.1 | 1.5 | 2.2 | ||

| MDC-K25 | 25 | L/min | 36.5 | 36.2 | 35.7 | 35.2 | 34.6 | 33.2 | 32.4 | 31 |

| KW | 0.55 | 0.75 | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | ||

| MDC-K32 | 32 | L/min | 46 | 46 | 45 | 44 | 44 | 43 | 42 | 41 |

| KW | 0.75 | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | 3 | 4 | ||

| MDC-K40 | 40 | L/min | 57 | 57 | 56 | 56 | 55 | 53 | 51 | 50 |

| KW | 0.75 | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 4 | ||

| MDC-K50 | 50 | L/min | 72 | 71.7 | 71.5 | 71 | 69 | 67 | 65 | 63 |

| KW | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 4 | 5.5 | ||

| MDC-K63 | 63 | L/min | 91.5 | 91 | 90.6 | 90 | 89 | 86.7 | 85.7 | 84 |

| KW | 1.5 | 2.2 | 2.2 | 3 | 3 | 4 | 5.5 | 5.5 | ||

| MDC-K80 | 80 | L/min | 119 | 119 | 119 | 118 | 116 | 110 | 106 | 99 |

| KW | 1.5 | 2.2 | 3 | 3 | 4 | 5.5 | 5.5 | 7.5 | ||

| MDC-K100 | 100 | L/min | 148 | 147 | 144 | 143 | 142 | 138 | 135 | 132 |

| KW | 1.5 | 2.2 | 3 | 4 | 4 | 5.5 | 7.5 | 11 | ||

| MDC-K112 | 112 | L/min | 157 | 156 | 154 | 153 | 151 | 150 | 145 | 140 |

| KW | 2.2 | 3 | 3 | 4 | 5.5 | 7.5 | 7.5 | 11 | ||

| MDC-K125 | 125 | L/min | 183 | 179 | 175 | 171 | 168 | 161 | 155 | 150 |

| KW | 3 | 3 | 3 | 4 | 5.5 | 7.5 | 11 | 11 | ||

| MDC-K150 | 150 | L/min | 219 | 215 | 211 | 207 | 204 | 195 | 187 | 179 |

| KW | 4 | 4 | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 | ||

| MDC-K180 | 180 | L/min | 260 | 256 | 252 | 248 | 245 | 236 | 228 | 221 |

| KW | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 | 11 | 15 | 15 | ||

| MDC-K200 | 200 | L/min | 290 | 287 | 284 | 281 | 278 | 271 | 264 | 257 |

| KW | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 15 | 18.5 | ||

| MDC-K250 | 250 | L/min | 356 | 352 | 348 | 344 | 341 | 334 | 327 | 321 |

| KW | 4 | 5.5 | 7.5 | 7.5 | 11 | 15 | 18.5 | 22 | ||

| MDC-K350 | 350 | L/min | 455 | 450 | 446 | 442 | 439 | 431 | 424 | 418 |

| KW | 5.5 | 7.5 | 11 | 11 | 15 | 18.5 | 22 | 30 | ||

| MDC-K400 | 400 | L/min | 579 | 573 | 567 | 562 | 557 | 545 | 535 | 524 |

| KW | 7.5 | 11 | 11 | 15 | 18.5 | 22 | 30 | 30 | ||

| MDC-K500 | 500 | L/min | 719 | 712 | 707 | 701 | 696 | 684 | 673 | 662 |

| KW | 11 | 15 | 15 | 18.5 | 22 | 30 | 37 | 45 | ||

| MDC-K630 | 630 | L/min | 902 | 894 | 887 | 880 | 874 | 858 | 845 | 834 |

| KW | 15 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | ||

*The above characteristic testing is based on water transfer at normal speed under 20°C. The performance parameter error is approximately ±10%. Pump performance varies depending on the proportion and density of the liquid medium.

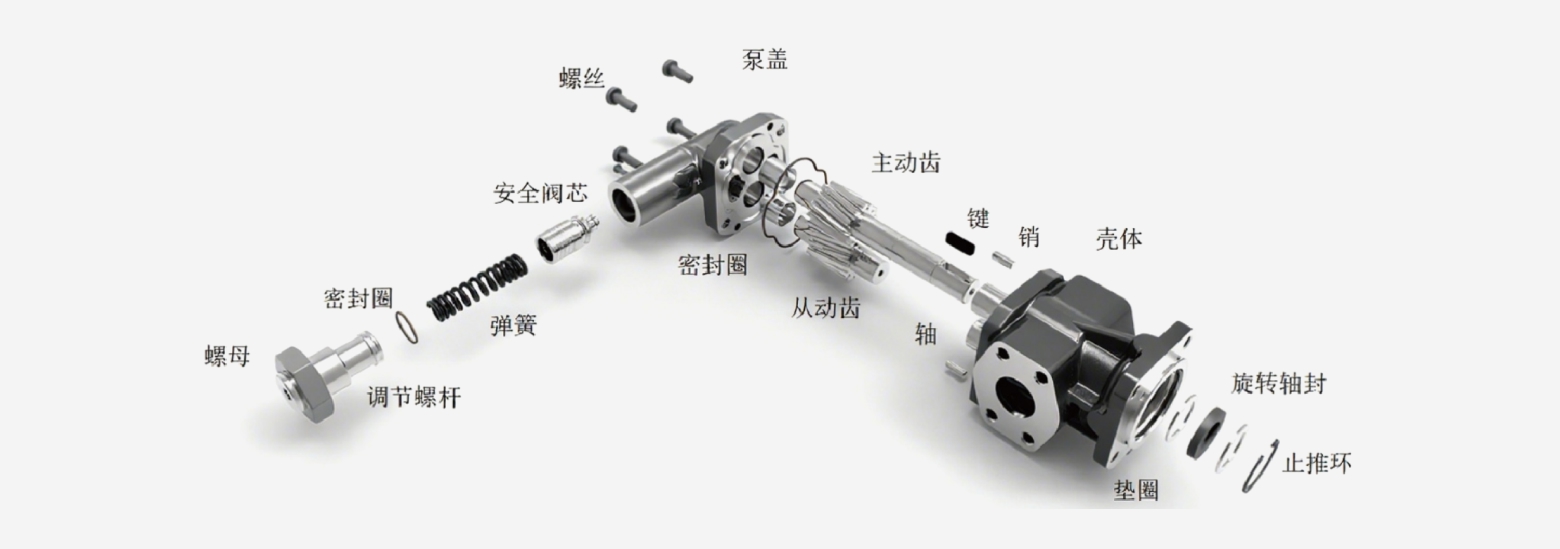

Pump Structure

The MDC-K Pump production structure consists of the Pump Cover, Active Gear, Driven Gear, Gear Shaft, Pump Body, Rotary Shaft Seal, Safety Valve Core, Adjusting Screw, and Gasket, forming a high-precision leak-proof fluid transfer assembly.

Working Condition

| Flow | Rotational speed | Ambient Temperature | Inlet vacuum degree | Pressure difference | System withstand pressure |

|---|---|---|---|---|---|

| 4ml/rev~630ml/rev | 100~3000rpm | -40°C~+250°C | -0.5Bar | 0-25bar | 35Bar |

Application Area

New energy high-low temperature testing, generator/transmission/gearbox lubrication, fuel transfer, waste oil treatment, refrigeration medium transportation, general machinery lubrication, cooling, hydraulic systems, etc.