How Does a Positive Displacement Pump Work?

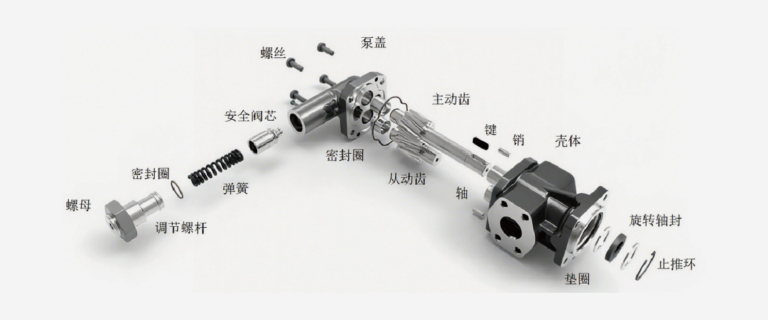

In a gear pump, two meshing gears trap fluid between their teeth and the housing as they rotate. Each revolution pushes the same volume through — no more, no less. Vane pumps work differently: a spinning rotor with retractable vanes creates expanding and compressing chambers inside the housing, moving fluid from the inlet to the outlet. Either way, the volume per cycle is locked in by the physical geometry. That's why output stays consistent regardless of system pressure — it's a mechanical certainty, not something that needs to be tuned.

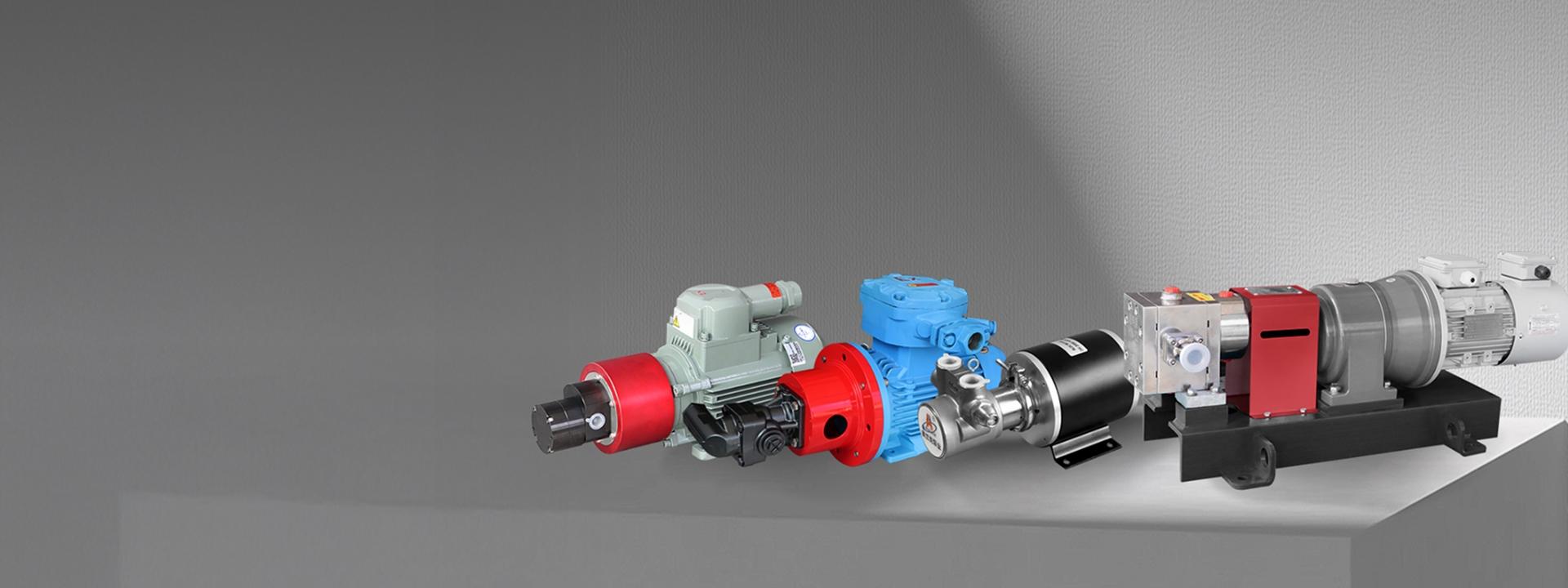

Gear Pump vs. Vane Pump — Which One Fits Your Application?

Gear pumps are the more versatile option. They handle a wider viscosity range, work well under high pressure, and are available in both magnetic drive and mechanical seal versions. Good for metering, chemical transfer, lubrication, and most continuous-flow industrial applications.

Vane pumps are the better choice when you need smooth, low-pulsation flow at moderate pressures. The (P)-VP series specifically handles high-pressure scenarios where flow needs to decrease gradually as pressure rises — useful in hydraulic and cooling systems where sudden pressure spikes need to be avoided.

If viscosity is high or the media is hazardous, gear pump. If smooth flow at moderate to high pressure matters more, vane pump.

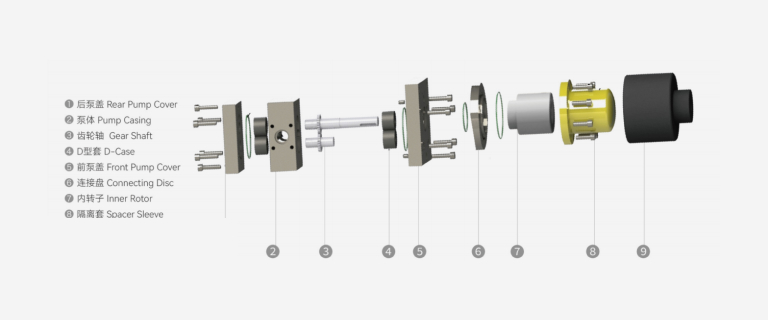

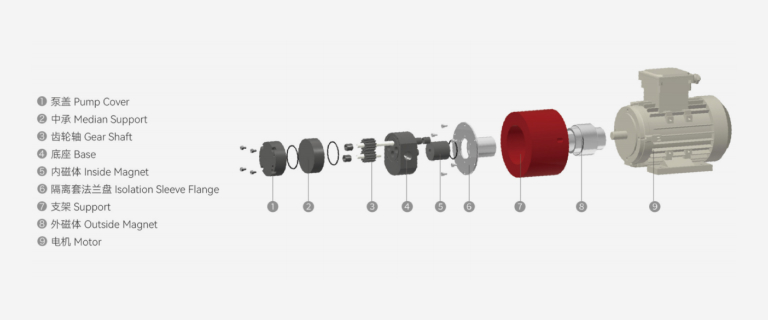

Magnetic Drive vs. Mechanical Seal in Gear Pumps

Gear pumps have one extra thing to deal with compared to other pump types — the gear mesh generates heat and wear, so whatever seal you're running has to handle that on top of media pressure. Magnetic drive gear pumps sidestep the problem entirely: no shaft penetrates the casing. The inner rotor is driven through an isolation sleeve via magnetic coupling. There's no physical path for fluid to get out. That's why MDC-X and MDC-M are the default pick for anything toxic, corrosive, or volatile.

MDC-K takes a different approach — dual seal, primary shaft seal plus a secondary safety barrier. It also has a safety valve core built in for pressure relief if the system backs up. Good for media that isn't fully hazardous but still needs solid leak prevention.

How to Select the Right Positive Displacement Pump

Start with three parameters: what you're pumping (media type and viscosity), at what temperature, and at what pressure. Viscosity narrows it down fast — anything above a few hundred cP and you're in gear pump territory. Temperature range determines which series fits: MDC-M for cryogenic, MDC-X or MDC-K for high temperature. Pressure requirement then guides the specific model — MDC-M handles up to 100bar, (P)-VP up to 16bar, MDC-X above 5MPa for sustained high-pressure duty.

If your media is hazardous, magnetic drive is non-negotiable. If noise matters, check the dB rating — MDC-X and MDC-K are both rated for low-noise environments. And if none of the standard models fit your exact requirements, ODM configuration is available.

Positive Displacement Pump vs. Centrifugal Pump — When to Use Which

| Factor | Positive Displacement Pump | Centrifugal Pump |

|---|---|---|

| Flow consistency | Fixed output per revolution, pressure-independent | Flow drops as system pressure increases |

| Viscosity handling | Up to 20,000 cP | Best for low to moderate viscosity |

| Self-priming | Good across most types | Requires priming or submersion |

| Metering precision | Down to 1% accuracy | Not suited for precision metering |

| High-pressure capability | Up to 100bar (MDC-M) | Generally lower pressure range |

| Flow volume | Small to medium | Medium to large |

| Best for | Dosing, metering, high viscosity, hazardous media | Continuous high-volume transport |