In the landscape of industrial fluid handling, standard centrifugal pumps often dominate the discussion. However, when a system requires high discharge pressures at relatively low flow rates, or needs to handle fluids with entrained gas, the standard centrifugal design frequently encounters efficiency barriers or operational instability. This is where the vortex water pump (often technically referred to as a regenerative turbine pump or peripheral pump) becomes the engineered solution of choice.

A vortex pump is a kinetic machine that bridges the hydraulic gap between positive displacement pumps and centrifugal pumps. Unlike a centrifugal pump that imparts energy to the fluid in a single pass through the impeller, a vortex pump relies on a regenerative process where the fluid circulates between the impeller vanes and the casing channel multiple times. This mechanism allows for the generation of significant pressure heads in a compact footprint, making it indispensable for precision industries such as semiconductor manufacturing, chemical processing, and thermal management.

This guide will dissect the technical mechanics, hydraulic characteristics, and selection criteria for these pumps, referencing specific capabilities found in Aulank’s PWH, WK, and WD series.

Understanding the Working Principle of a Regenerative Turbine Pump

To grasp the utility of a vortex pump, one must first understand the regenerative turbine pump working principle. While it is classified kinetically as a rotodynamic pump, its internal fluid dynamics differ vastly from a volute centrifugal pump.

The core component is the impeller, which features radial vanes machined into its periphery. As the impeller rotates, fluid enters the suction port and is directed into the annular channel surrounding the blades. Centrifugal force pushes the liquid outward to the periphery of the impeller. However, instead of leaving the casing (as in a standard centrifugal pump), the fluid is deflected by the pump casing liner back into the root of the next impeller vane.

This recirculation creates a spiral or "vortex" motion. Each time the fluid re-enters the vane, it gains additional kinetic energy. This phenomenon, known as "regeneration," allows the pump to build pressure incrementally as the fluid travels from suction to discharge. Consequently, a small industrial water pump using this design can generate heads equivalent to a much larger multistage centrifugal pump.

This specific hydraulic action is why these pumps are critical for applications requiring a low flow high head pump. The energy transfer is cumulative, enabling the handling of system resistance that would otherwise stall a standard centrifugal unit of similar physical size.

Peripheral Pump Construction: The Recessed Impeller Advantage

In technical nomenclature, the term "vortex pump" is sometimes used interchangeably with peripheral pump. The construction of these units is defined by tight internal clearances and specific casing geometries.

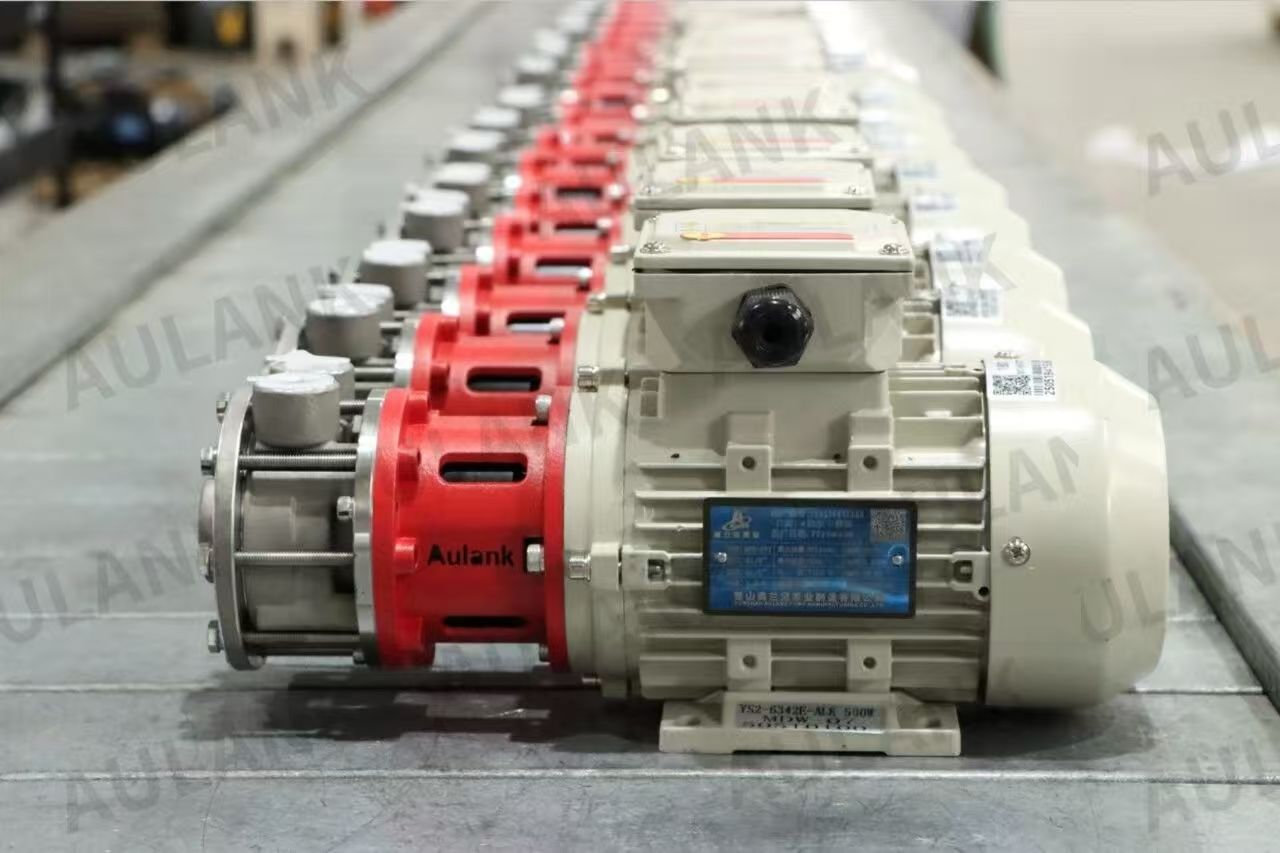

The Aulank vortex impeller design is engineered to balance hydraulic efficiency with operational stability. For instance, in the WD and WD-W series (available in Brass or Stainless Steel), the impeller is housed within a casing that minimizes internal recirculation losses while maintaining the necessary gap to prevent mechanical contact. This construction is vital for maintaining the steep performance curve characteristic of this pump type.

However, standard peripheral pumps are notoriously sensitive to solids. To address this, Aulank’s WK High-Head Vortex Pump and WL Vertical Vortex Pump utilize modified structural designs. By employing a recessed impeller vs open impeller configuration in specific models, the pump creates a hydraulic vortex that allows fluid to flow through the casing with minimal blade contact. This adaptation is crucial when the media is not perfectly clean water but may contain fine particulates typical in industrial cooling loops.

Pump casing materials play a significant role here. Aulank provides options ranging from Cast Iron and Ductile Iron for general industrial use, to Stainless Steel (304/316) and Fluoroplastic linings (F46/PFA) for chemical compatibility. The choice of material dictates the pump's longevity, particularly when handling aggressive media in a chemical process pump selection scenario.

Vortex Impeller Pump Performance Characteristics vs. Centrifugal Pumps

Engineers must understand the distinct pump performance curve explanation for vortex pumps compared to standard centrifugal options.

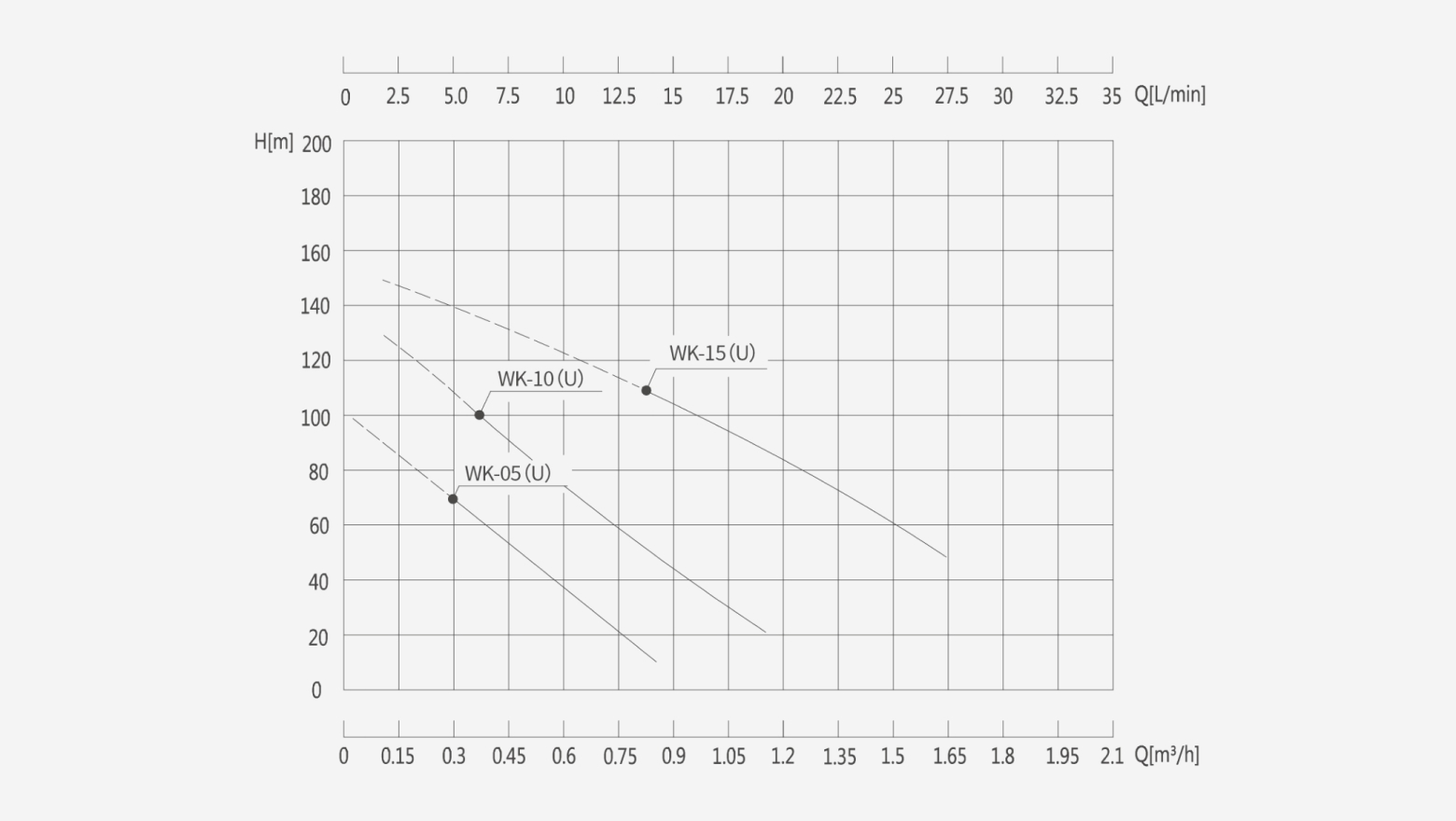

A standard centrifugal pump has a relatively flat head-capacity curve. In contrast, a vortex impeller pump exhibits a steep performance curve. This means that small changes in capacity result in significant changes in head pressure, and conversely, the flow rate remains relatively stable even if the system pressure fluctuates.

Key Performance Traits:

- Steep H-Q Curve: The discharge head rises sharply as flow decreases. This makes the pump ideal for applications where a constant flow is not required, but maintaining system pressure is critical.

- Power Curve: Unlike centrifugal pumps where power consumption drops at shut-off (zero flow), the power consumption of a regenerative pump vs centrifugal pump increases as the flow rate decreases, peaking at shut-off. Therefore, these pumps should never be operated against a closed discharge valve without a relief mechanism.

- Efficiency Window: These pumps excel in the specific hydraulic zone of low specific speed—where flow is low (e.g., 0.5 to 15 m³/h) and head is high (up to 150m or more).

This characteristic makes them a superior multistage pump alternative. Instead of installing a bulky, expensive vertical multistage pump for a 5 m³/h, 60m head requirement, a compact single-stage Aulank WK series pump can achieve the same duty point with a much small footprint pump design.

Why Use a High-Head Low-Flow Pump for Industrial Systems?

The primary value proposition of the Aulank product line lies in its classification as a high-head low-flow pump. Many modern industrial processes require precise temperature control or injection, which dictates high pressure to overcome heat exchanger resistance or nozzle back-pressure, but do not require massive volumes of liquid.

Consider a high pressure coolant pump application in CNC machining or a boiler feed water pump types selection for small steam generators. A standard centrifugal pump sized for the required pressure would produce excessive flow, leading to throttling (wasting energy) or cavitation. A positive displacement pump could work but adds complexity with pulsation dampeners and relief valves.

The vortex pump fits this niche perfectly. It provides the linear flow stability needed for a high temperature circulation pump in mold temperature controllers (TCUs) without the complexity of pistons or gears.

Data Comparison: Vortex vs. Centrifugal vs. Positive Displacement

| Feature | Vortex / Regenerative Turbine Pump | Standard Centrifugal Pump | Positive Displacement (Gear/Vane) |

| Flow/Head Profile | Low Flow / High Head | High Flow / Low-Med Head | Constant Flow / High Pressure |

| Curve Shape | Steep | Flat | Vertical (Linear) |

| Gas Handling | Excellent (up to 50%) | Poor (Vapor Lock) | Good |

| Fluid Viscosity | Low Viscosity only | Low to Medium | High Viscosity |

| Pulsation | None (Continuous) | None | Yes (Requires dampening) |

| Space Requirement | Compact | Medium to Large | Medium |

Table 1: Comparative analysis of pump technologies for industrial applications.

According to a 2024 industrial market analysis by Grand View Research, the demand for intelligent and energy-efficient fluid handling systems in the Asia-Pacific region is driving the adoption of specialized pumps that reduce oversized equipment in manufacturing sectors. This trend validates the shift toward compact, energy efficient industrial pumps like the Aulank vortex series for targeted cooling and transfer tasks.

Handling Entrained Gas: The Unique Capability of Gas-Liquid Mixing Pumps

One of the most frequent causes of pump cavitation problems and air binding in standard pumps is the presence of entrained gas. When gas bubbles enter the eye of a standard centrifugal impeller, they accumulate, blocking the liquid path and causing the pump to lose prime.

Aulank’s WD and WD-W series act as a specialized gas-liquid mixing pump. Due to the regenerative action of the impeller, gas bubbles are broken down into microscopic sizes and carried through the casing along with the liquid. The fluid velocity within the mixing channel effectively scrubs the bubbles from the impeller vanes.

This capability allows Aulank vortex pumps to handle fluids containing up to 50% entrained gas without vapor locking. This feature is critical for:

1. Dissolved air flotation pump (DAF) systems in wastewater treatment.

2. Micro bubble generator pump applications for ozone injection.

3.Evaporative cooling systems where the fluid may approach boiling point.

By acting as a self priming vortex pump, these units can evacuate air from the suction line (provided the casing contains initial liquid), simplifying system design by removing the need for external vacuum pumps or foot valves in specific configurations.

WD Brass/Stainless Steel Vortex Pump for High-Temperature Water & Oil Circulation

WD-W Brass/Stainless Steel Vortex Pump for High-Temperature Hot Water & Oil Transfer

Zero-Leakage Solutions: The Canned Motor Vortex Pump

In sectors like Semiconductor manufacturing and New Energy, leakage is not merely a maintenance nuisance—it is a safety hazard and a contamination risk. This necessitates the use of a canned motor vortex pump.

Aulank’s PWH, PWD, and PWM series integrate the vortex hydraulic design with a hermetically sealed canned motor structure. Unlike a standard pump coupled to a motor, the canned motor pump consists of a single unit where the stator and rotor are isolated by a non-magnetic corrosion-resistant liner (can). The pumped fluid circulates through the rotor chamber, lubricating the slide bearings and cooling the motor.

Advantages of Canned Motor Technology:

- Zero Leakage: No mechanical seals to fail. This is vital for cryogenic liquid transfer pump applications (-196°C) or high-temperature fluids (+400°C) where seal elastomers would degrade.

- Compact Design: The absence of a coupling and alignment requirement significantly reduces the installation footprint.

- Noise Reduction: Pump noise reduction is inherent in the design, as the water jacket dampens motor noise, making it suitable for quiet laboratory or cleanroom environments.

When comparing a magnetic drive turbine pump versus a canned motor design, the canned motor often offers superior heat dissipation for extreme temperature applications (High Temp +400°C) as established in Aulank’s product specifications.

PWH Stainless Steel Canned Vortex Pump for Industrial Fluid Transfer

PWD Stainless Steel Canned Vortex Pump for Chemical Liquid Handling

PWM Stainless Steel Canned Vortex Pump for High-Pressure Fluid Circulation

Key Applications for Industrial Turbine Pumps in Process Manufacturing

The versatility of the industrial turbine pump (another synonym for vortex pump) allows it to serve as the heartbeat of various specialized subsystems.

Semiconductor & Electronics:

In the wet bench process, a peripheral pump applications focus involves the circulation of deionized water and dielectric fluids. The Aulank stainless steel regenerative pump ensures that no metallic contamination (ions) is introduced into the ultra-pure water (UPW) stream, complying with cleanroom standards.

New Energy & Batteries:

For hydrogen fuel cell cooling and lithium battery electrolyte filling, pumps must handle specific gravities and viscosities while maintaining pressure. A hastelloy pump chemical resistance profile (available in customized Aulank solutions) is often required to withstand the corrosive nature of electrolytes.

Thermal Control Systems:

This is the home turf for Aulank. From injection molding temperature controllers to boiler feed water pump types, the ability to handle rapid temperature swings from -196°C (Liquid Nitrogen range) to +400°C (Thermal Oil) without mechanical seal failure causes such as thermal shock is a defining capability of the PWH series.

Selection Guide: Sizing a Small Kinetic Pump for Your System

Selecting the correct small kinetic pump requires more than just matching flow and head. A rigorous technical evaluation is necessary to ensure long-term reliability.

1. Duty Point & System Curve:

Identify the intersection of the pump system curve and the pump performance curve. For vortex pumps, ensure the duty point is to the right of the shut-off head to prevent over-pressure, but not so far right that it operates at low efficiency. Duty point selection is critical to avoid motor overload.

2. NPSH Calculation:

NPSH calculation for vortex pumps is vital, especially for hot fluids or volatile solvents. The Net Positive Suction Head Available (NPSHa) must exceed the NPSH Required (NPSHr). Vortex pumps generally require higher NPSH than standard centrifugal pumps. If the fluid dynamics in pumps suggests a risk of cavitation, Aulank recommends a flooded suction installation or increasing the static head on the suction side.

3. Viscosity Considerations:

The viscosity effect on pump performance is more pronounced in vortex pumps than in positive displacement pumps. As viscosity increases, the friction losses in the tight clearances of the regenerative channel increase rapidly, degrading head and efficiency. These pumps are best suited for low-viscosity fluids (typically under 50 cSt).

4. Material Compatibility:

For sea water or brine, a brass impeller pump (WD Series) offers excellent resistance to bio-fouling and corrosion. For acidic environments, a chemical process pump selection should lean towards Stainless Steel 316 or lined options.

5. Installation & Maintenance:

Proper vertical inline pump installation (for WL series) saves floor space. A comprehensive industrial pump maintenance guide should include monitoring of impeller clearance adjustment. Over time, wear on the impeller vanes or casing liner will widen the gap, reducing pressure capability. Regular inspection allows for timely parts replacement to restore the hydraulic efficiency formula parameters to factory standards.

Conclusion

The vortex water pump is a masterpiece of hydraulic engineering, solving the specific challenges of high-pressure, low-flow, and gas-entrained fluid transfer that traditional pumps cannot address efficiently. Whether utilizing the Aulank PWH series for extreme temperature control (-196°C to +400°C) or the WD series for gas-liquid mixing, understanding the unique attributes of the regenerative turbine principle is the key to optimizing your process system.

By selecting a pump that is purpose-built for these parameters, engineers can eliminate the need for oversized multi-stage units, reduce vibration analysis in pumps issues related to cavitation, and achieve a stable, leak-free operation.

For detailed performance curves and specific model configurations regarding our High-Head Vortex Pumps and Canned Motor Solutions, please visit the Aulank Product Catalog.

References:

- Grand View Research. (2024). Industrial Pump Market Size, Share & Trends Analysis Report By Product (Centrifugal, Positive Displacement), By Application (Water & Wastewater, Oil & Gas), By Region, And Segment Forecasts, 2024 - 2030.